07 December 2015

|

|

Refrigerant gases play a vital role in cold storage and industrial refrigeration but if a leak occurs, the impact can be costly.

Shaun Evers, managing director of Stonegate Instruments, explains how sophisticated new gas detection technologies can cut down on gas leaks and save on the related costs. Energy consumption in the refrigeration sector costs British industry approximately £300 million each year with the average annual site energy bill for a cold store totalling £0.5 million. Many refrigeration units currently in use are outdated, having been designed and built over 20 years ago, at a time when energy efficiency was not the issue it is today. As a result, they are not operating efficiently and are using huge amounts of unnecessary energy, as well as costing more than necessary to keep in operation. |

Gas leaks are one problem area which can have a huge effect on the amount of energy by consumed by a cold store. According to a study by the Institute of Refrigeration (IOR) and the Carbon Trust, a leak of just 1kg of refrigerant gas can cause the same environmental damage as driving a van 10,000 miles. With leaks of up to 30% of the charge during a year not uncommon, the need for preventative measures is essential, not only to save your own costs but also to cut down on the environmental impact.

Leak Factors

A number of factors can lead to leaks occurring. Equipment failure, improper maintenance work, mechanical damage, and accidental release during refrigerant replenishment can all cause a potentially damaging leak. Reducing leakages not only saves energy, as a leaking refrigeration system has to work harder to maintain temperatures, but it also reduces unnecessary costs on energy bills.

Whilst gas leaks are similarly hazardous both to a company’s bottom line and to the environment, the solution is quite simple - gas detection systems are a vital piece of equipment that offer peace-of-mind to cold store owners and operators.

The use of a gas detection system can help ensure that leaks are identified and repaired, which is especially essential just before the refrigerant gas is topped up. This is not only to minimise environmental damage or the impact on the health and safety of the workforce but it is actually a legal requirement and is part of the EU F-Gas Regulations.

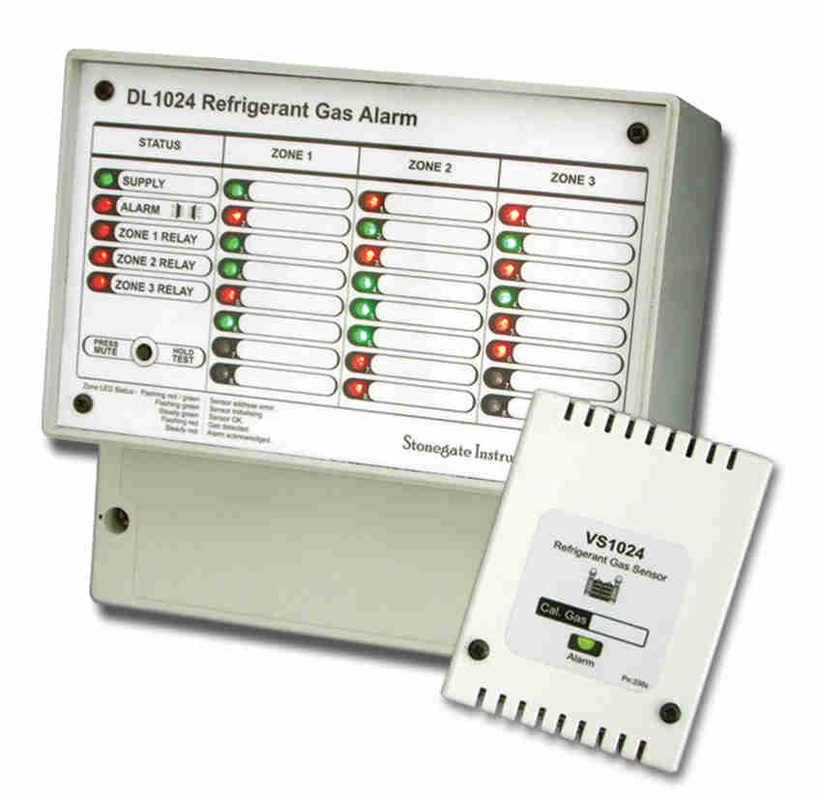

Stonegate’s gas detection system detects a wide variety of refrigerants and accommodates up to 24 remote refrigerant sensors. The sensors are arranged in three zones of eight channels with four relay outputs for signalling an alarm, one for each zone.

LED colours indicate the presence and status of each sensor and any sensed gas leak sends an audio and visual alarm to alert staff members immediately so that the problem can be quickly rectified.

Whilst gas leaks are similarly hazardous both to a company’s bottom line and to the environment, the solution is quite simple - gas detection systems are a vital piece of equipment that offer peace-of-mind to cold store owners and operators.

The use of a gas detection system can help ensure that leaks are identified and repaired, which is especially essential just before the refrigerant gas is topped up. This is not only to minimise environmental damage or the impact on the health and safety of the workforce but it is actually a legal requirement and is part of the EU F-Gas Regulations.

Stonegate’s gas detection system detects a wide variety of refrigerants and accommodates up to 24 remote refrigerant sensors. The sensors are arranged in three zones of eight channels with four relay outputs for signalling an alarm, one for each zone.

LED colours indicate the presence and status of each sensor and any sensed gas leak sends an audio and visual alarm to alert staff members immediately so that the problem can be quickly rectified.

Unnoticed Gas Leaks

Technology plays a vital role in the early identification and stoppage of leaks. This is particularly prevalent when you consider that 60% of gas escapes before an employee notices, showing that it can’t be left to the workforce to notice when leaks occurs. Gas detector systems are perfect for providing constant coverage of the whole of the cold store, to stop leaks quickly and to minimise potential damage.

EU F-Gas legislation states that cold stores with a charge of 3-30kg must be tested for gas leaks once a year, cold stores with a charge of 30kg or more must be tested twice a year, and all units with a charge of over 300kg must have a fixed gas detector installed. These gas detectors must have a sensitivity of 5g/year and should be checked after 25 hours of continuous use. They should also be calibrated with a 1,000ppm gas to air mix.

Stonegate’s DL1024 gas detector meets all these requirements. Stonegate’s gas detection system can be programmed to detect a wide range of both toxic and non-toxic gases, including CFCs, HCFCs, HFCs and CO2. The gas detector also has a battery back up so it will still work in a power cut, a time which could be more risky than normal for gas leaks.

With the installation of a Stonegate gas detection system a business can reduce energy costs, cut carbon emissions, and demonstrate corporate responsibility. With a payback period of less than two years, this technology offers a simple solution for businesses across all sectors.

EU F-Gas legislation states that cold stores with a charge of 3-30kg must be tested for gas leaks once a year, cold stores with a charge of 30kg or more must be tested twice a year, and all units with a charge of over 300kg must have a fixed gas detector installed. These gas detectors must have a sensitivity of 5g/year and should be checked after 25 hours of continuous use. They should also be calibrated with a 1,000ppm gas to air mix.

Stonegate’s DL1024 gas detector meets all these requirements. Stonegate’s gas detection system can be programmed to detect a wide range of both toxic and non-toxic gases, including CFCs, HCFCs, HFCs and CO2. The gas detector also has a battery back up so it will still work in a power cut, a time which could be more risky than normal for gas leaks.

With the installation of a Stonegate gas detection system a business can reduce energy costs, cut carbon emissions, and demonstrate corporate responsibility. With a payback period of less than two years, this technology offers a simple solution for businesses across all sectors.

Stonegate Instruments Ltd designs, develops and manufactures electronic equipment for the refrigeration industry. The company’s products are proven in cold storage facilities for reducing energy, carbon emissions and the associated costs. For more information, visit www.stonegate-instruments.com.

Content continues after advertisements