13 August 2019

|

A-Gas Rapid Recovery technical and training manager Roger Smith on the crucial role refrigerant reclamation is playing in the industry.

A-Gas has been working hard to extend its range of reclaimed gases available to customers. We have invested heavily in expanding reclamation facilities in the UK and in Holland as the industry rises to the low GWP challenge.

A-Gas has been working hard to extend its range of reclaimed gases available to customers. We have invested heavily in expanding reclamation facilities in the UK and in Holland as the industry rises to the low GWP challenge.

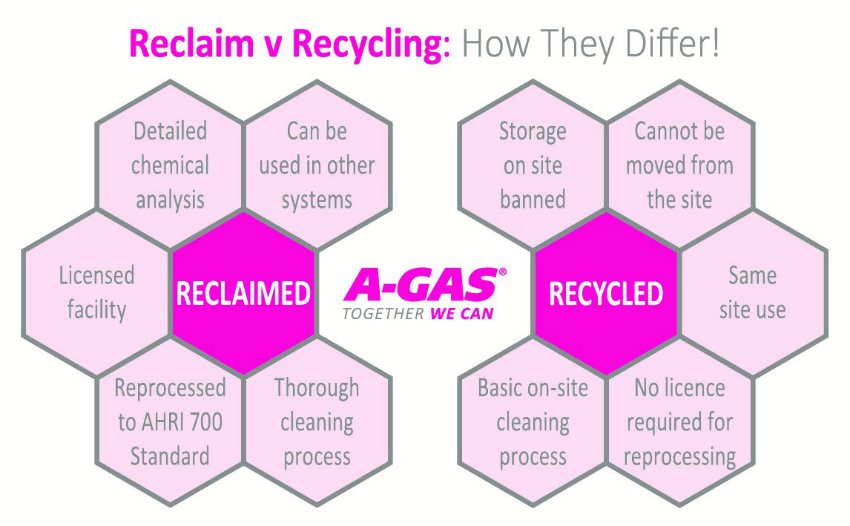

| We have built two new tanks at our site in Portbury near Bristol to increase our storage capacity for reclaimed refrigerants. A-Gas also has a base in Holland at Eygelshoven which houses a new refrigerant reclamation facility and this is expected to make an impact on supplies later this year. Momentum is with A-Gas Rapid Recovery after its launch in Continental Europe at the Chillventa exhibition last year. This quick and easy way to recover refrigerant on site at short notice has impressed customers at home and abroad. They have told us that they like the way it saves time on site and reduces costs, while helping to maintain business as usual for the customer. Purified and guaranteed Refrigerant recovery is beginning to play a bigger role in our industry as the 2020 ban on the use of high GWP virgin refrigerant (above 2500 GWP) looms. One of the questions we are often asked at A-Gas is what is the difference between recycled and reclaimed product? I will explain how they differ. Reclaimed refrigerant is a gas that has been reprocessed by a licensed facility to the industry standard AHRI 700 to match that of virgin product. It is refrigerant that is purified, certificated and guaranteed. A refrigerant that has been recycled is an uncertified product that is being returned for use on the same site and has not been moved between premises. It’s a used refrigerant that should have gone through a basic, on site, cleaning process, normally carried out by the contractor completing the work. Unprocessed refrigerant recovered from a system cannot be stored on site for longer than a year due to issues around landfill. As soon as you move it from the site – unprocessed or recycled – it is classed as hazardous waste and must be sent, with the appropriate legal environmental paperwork, to a licensed facility for reprocessing or disposal. This is where A-Gas can make a difference for contractors and end users. We process the waste refrigerant back into AHRI certified product and this helps to reduce the short-term impact of the F-Gas phase downs on the industry. We are reclaimed refrigerant specialists and don’t sell recycled gas at all. Refrigerant sent to our reprocessing centres becomes fully reclaimed product and is returned to the market in line with the AHRI 700 standard. At Portbury and Eygelshoven used refrigerant undergoes chemical analysis, is cleaned of contaminants and goes through our separation plant to produce a product that matches that of virgin refrigerant requirements. You should be aware that a product can change composition through its life if the system has experienced leaks. This is particularly true for blends of refrigerants, such as the R407 family. Installers should act on the side of caution when looking to re-use recycled products that are not single component refrigerants. A-Gas offers a refrigerant analysis service at its custom-built lab in Portbury where it can confirm a refrigerant’s composition, purity and help relieve that uncertainty. Reassurance for contractors Our job is to ensure that our reclaimed refrigerant meets the same standard as virgin product. This means it is reprocessed to AHRI 700 standard and can be sold to be used in other systems. When buying reclaimed refrigerant you know it has been returned to the same standard as virgin material. This gives reassurance to the contractor and the end user and in turn ensures it performs as it should. Installers can be reassured that reclaimed refrigerant will not lead them to breach the F-Gas Regulations. Our investment in reclamation facilities highlights the commitment we have to providing the industry with the capacity and infrastructure to support the F-Gas phase downs. Our new separation equipment will enable us to reclaim mixed refrigerants from customers across Europe. This type of waste has changed over the years as refrigerant mixtures get more complicated and we start to see much higher quantities of mixed gases. Several different refrigerants combined together in one mix sets us new challenges and without separation technology it is almost impossible to return the gas to the same kind of quality as virgin material. A-Gas reclaims thousands of tonnes of refrigerant a year across the globe and investing in new reclamation facilities will ensure that we continue to be one of the world’s leading reclaimers of refrigerants. www.agas.com www.agasrapidrecovery.com |

Content continues after advertisements