25 October 2019

|

| Star Refrigeration has completed the manufacture and installation of a 75,000m3 cold store facility for Lineage Logistics at its new site in Great Haddon, near Peterborough. The project consists of 15,000 pallet spaces of frozen warehouse capacity as Lineage plans for future growth. Temperature-controlled logistics specialist Lineage has over 1.4 billion cubic feet of storage capacity worldwide, with 200 facilities in seven countries across North America, Europe and Asia. |

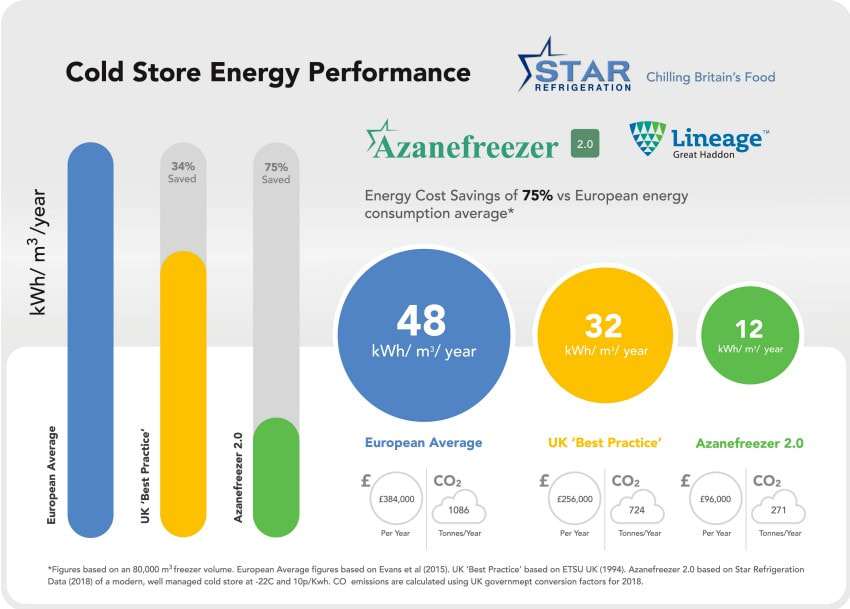

| The Peterborough project has seen the installation of a 75,000m3 cold store plant with a refrigeration capacity of 600kW. Results from recent energy performance data analysis indicate that the Azanefreezer 2.0’s annual energy usage is set to cut carbon emission by 453 tonnes of CO2 per year compared to the UK’s ‘Best Practice’ guidelines. According to the specifications provided by STS, Lineage required a 600kW refrigeration system, which was designed to achieve a nominal storage design temperature of -24 degrees Celsius. Running costs were key to the plants design, with STS specifying a minimum condenser surface of 4,800 m2 to achieve optimum condensing pressures throughout the year. Evaporator absorbed power was also limited to 35kW, while the condenser absorbed power should be equal to or less than 30kW in order to maximise efficiency and reduce electrical costs. Star Refrigeration was able to secure the contract through their offer of two independent AF300-S Azanefreezer 2.0 ammonia refrigeration plants. In order to adhere to STS’s technical specification, Star modified its existing AF300 unit by retaining the existing low-pressure receiver and compressors, but upgrading the unit’s condenser and base frame to a larger size. This allowed it to achieve a higher efficiency than that required by the tender, thus reducing running costs. The use of a larger condenser allowed the facility to operate on 32.2kW for its evaporators, an 8.1% improvement on STS’s requirement, and 12.5kW for its condenser, a 58.3% improvement. The Azanefreezer 2.0 is a modular, low charge packaged ammonia freezer with patented low pressure receiver design which is unique to Star Refrigeration. Its design allows for a reduction of the system’s ammonia refrigerant charge of up to 80% when compared to traditional pumped recirculation systems. Having all maintenance valves on the Azanefreezer 2.0 unit as well as the use of reverse cycle defrost make possible the elimination of hot gas valve stations at each cooler, including all the associated ventilation and gas detection components. Star says this is a significant benefit in terms of reducing the risk of refrigerant leakage and simplifying ongoing maintenance. The Azanefreezer 2.0 is assembled at Star’s manufacturing facilities and tested prior to dispatch which reduces onsite installation times and expenses. It does not require a plant room, eliminating third party costs by dispensing with the need for a significant amount of accompanying infrastructure. Also, the plant was designed to have no flanged or mechanical joints within the cold store itself, meaning there are no potential leakage points inside the store. Instead, all valves and mechanical joints are positioned on the exterior of the unit and at heights which make them easily accessible from a maintenance perspective. Jonathan Baker, Executive Director of Lineage Logistics in the UK, said: “Star Refrigeration were able to respond to the most stringent requests for quality and efficiency and provided a solution that exceeded the technical requirements specified to satisfy the facility’s cooling need. We are impressed with the advantages offered by Star’s Azanefreezer 2.0 and the smooth delivery of the project.” www.star-ref.co.uk |

Content continues after advertisements