08 May 2025

|

Working with a producer of portable blast chillers/freezers and cold stores that had historically used R-449A (GWP 1397), Derbyshire-based Ultra Refrigeration was looking to test a lower GWP refrigerant to reduce the environmental footprint of their new units, without compromising on the system performance.

Already in regular discussion, Climalife’s Technical Sales Director, Neil Roberts, and Ultra Refrigeration’s Operations Director, Anthony Lomas, considered the various refrigerant options available for the new unit designs taking into account predicted performance, product availability, safety and environmental credentials.

Several refrigerants were assessed, including CO₂ and options with a GWP below 150, but due to blast freezer capacity requirements and the need for easy transportation, Opteon XL40 | R-454A (GWP 239) emerged as the most suitable solution.

Neil Roberts said it was worth noting that the lowest GWP refrigerant is not always the best solution for a project. The location, cost, energy efficiency and reliability should all be considered too which is why it’s key to seek out the expert advice of companies like Climalife when specifying a new system.

He added: “Uncertainty around the changes in legislation often leads to a delay in taking decisions, so it’s great to be able to assist a manufacturer and end user with the foresight to get ahead of the imminent legislation changes by moving to a very low GWP, sustainable and energy efficient refrigerant option and potentially setting a new benchmark for others in the industry to follow.”

Ultra was very keen to future proof its equipment for the next 10-20 years at least and so commissioned a trial with their blast freezers using Opteon XL40 | R-454A, alongside an identical unit running under the same conditions, containing R-449A.

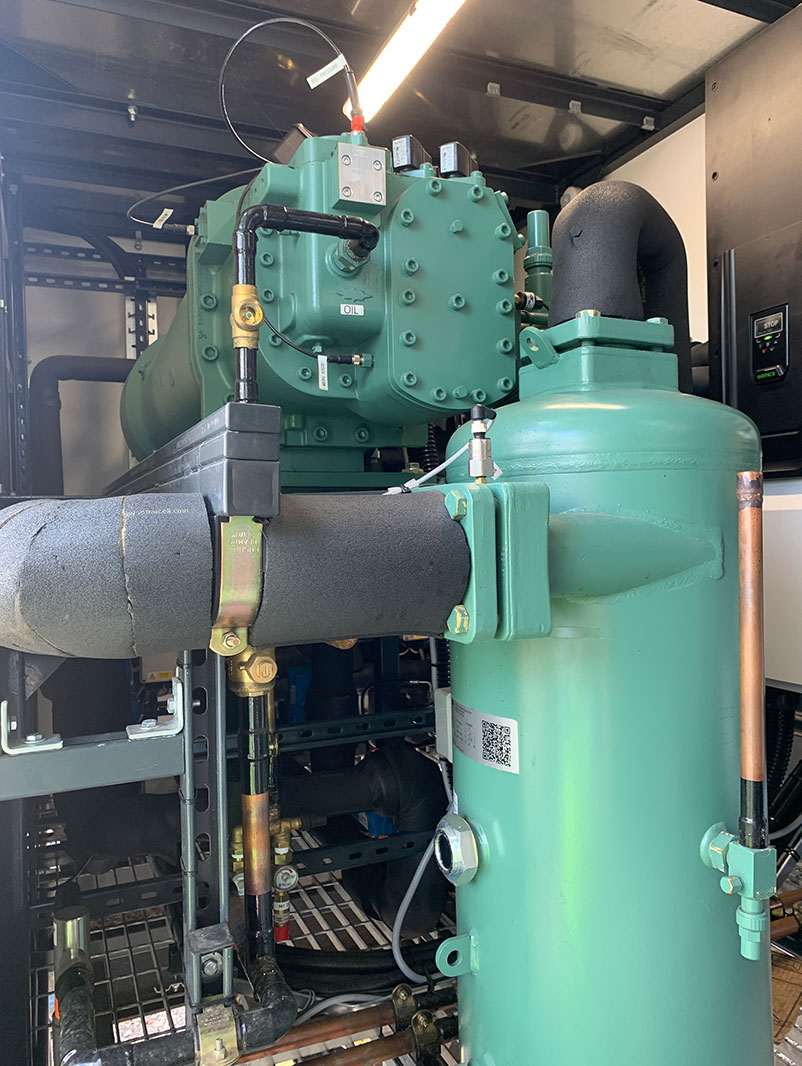

From left, R-449A blast freezer, R-454A cold store, R-454A test blast freezer

Trialling R-454A in cold storage and blast freezing applications

Cold stores

The cold store unit performed smoothly during testing, with some system adjustments made to accommodate pressure variations. Following successful trials, the unit is now in full production, with the first delivery to a client’s site completed in July 2024.

Blast chillers/freezers

The blast freezer trials revealed key differences in refrigerant performance. Initially, the R-454A unit did not operate as efficiently as the R-449A unit. Due to slight differences in pressure/temperature relationships, the existing control system — originally designed for R-449A — was self-limiting performance unnecessarily.

To address this, Ultra Refrigeration optimised the control system, allowing the R-454A unit to perform at a comparable level of efficiency to its R-449A counterpart with all of the environmental benefits.

During the testing phase, IBCs full of water were stored in the blast freezers to simulate product load

Pressure Equipment (Safety) Regulation

Any system with a pressure over 0.5 bar must comply with the Pressure Equipment (Safety) Regulation (PE(S)R). Systems are categorised from SEP (Sound Engineering Practice) to Category 4, based on factors such as system volume, pipe size, fluid risk category, and pressure.

- The R-449A system was classified as Category 1, using an A1 refrigerant (fluid group 2).

- The R-454A system fell under Category 2, using an A2L refrigerant (fluid group 1).

This change in classification required additional safety compliance measures, new component sourcing, and the involvement of a notified body to certify the system. Updates to welding, brazing certifications, and software were also necessary.

Anthony Lomas said: “Despite an initial steep learning curve and some additional costs, once the required changes were made, manufacturing the system was relatively straight forward and not significantly more complex than the previous design.”

Beyond the challenges: success in real-world applications

The time and effort invested in re-engineering the new system and meeting compliance requirements have proven worthwhile. Numerous cold storage units and blast chillers/freezers running on Opteon XL40 | R-454A are now operating on-site in real-world applications. End users are reportedly delighted with the performance, reinforcing the success of this transition.

Ultra continues to work on further product innovations with new unit designs aimed at enhancing energy efficiency, performance and ease of use expected to be released later this year.