19 March 2024

|

John Phipps, Commercial Director UK at A-Gas, examines the impact of cost when it comes to refrigerant choice.

A-Gas has pledged to become a Net Zero company by 2035 with our Towards Zero, Together mantra. The climate and refrigeration industry is on the same path, guided by the key drivers of quota, cost and ESG (Environmental, Social & Governance).

Quota is directly linked to governmental policy, which will potentially lead to a full phase-out of F-gases with a GWP of more than 150 by 2032. ESG is a mix of public perception and investment. Both of these are topics for future articles, while this article will focus on the cost driver and the inputs into that.

To begin the discussion we can split the costs into CAPEX and OPEX. As an employee of A-Gas, a supplier of gas, the focus is the OPEX area. The argument could be made that for a newly installed system the first charge is actually CAPEX and only subsequent top-ups are OPEX.

OPEX Discussion

Notwithstanding the comments above, if we begin with OPEX from a gas perspective then what are the main cost drivers on the Net Zero journey?

Clearly, the higher GWP refrigerants are becoming more scarce, and quota is restricting virgin import volumes, which leads to the simple economic supply and demand pricing to reach a market equilibrium price. This pressure affects the > 150 GWP synthetics but does not affect the new generation of A2L refrigerants, the natural A3 hydrocarbon-based or natural refrigerants such as ammonia or CO2. The OPEX costs for higher GWP gases will rise over time due to simple market economics.

Based on the current low availability of sub-150 GWP refrigerants, the production costs and their patents will keep the market price mostly matching the higher GWP synthetics. Heat pumps are moving toward propane (R290), but we are focusing on chilling, not heating, so what about the OPEX of CO2 (R744) or ammonia (R717)?

For this article I will focus on CO2. Cost per kg, it is significantly less than R407F, R404A or R410A, and it is a great potential alternative due to its zero ozone depletion potential (ODP) and a global warming potential (GWP) of 1, compared with several thousand for some synthetics. But what about the performance (we are ignoring the CAPEX portion as this certainly isn’t a drop-in solution)?

A CO2 refrigeration system suffers performance degradation in warm or hot climatic regions as it operates in its supercritical region. (Bruno, F.; Belusko, M.; Halawa, E, 2018) conducted a comprehensive review of CO2 refrigeration systems with the transcritical operation considered a significant factor.

The study noted that using CO2 is a challenge due to the system operating in a supercritical state. This means heat rejection capacity is degraded, reducing the coefficient of performance (COP) of cooling.

This review concludes that although the system analysis shows that the expansion process during transcritical operation is the process that contributes to the largest exergy destruction in the CO2 cycle - This is mainly due to the high pressure of gas exiting the gas cooler that must be expanded to enable the cooling effect in the evaporator. Energy performance is comparable to systems using other refrigerants, and, as we know, for supermarket refrigeration, the OPEX cost of gas is a big factor.

Research by (Yang.D, Li.Y, Xie.J, Wang. J 2022) noted that for supermarket refrigeration, the application of transcritical CO2 technology is the most mature, but energy consumption is a concern.

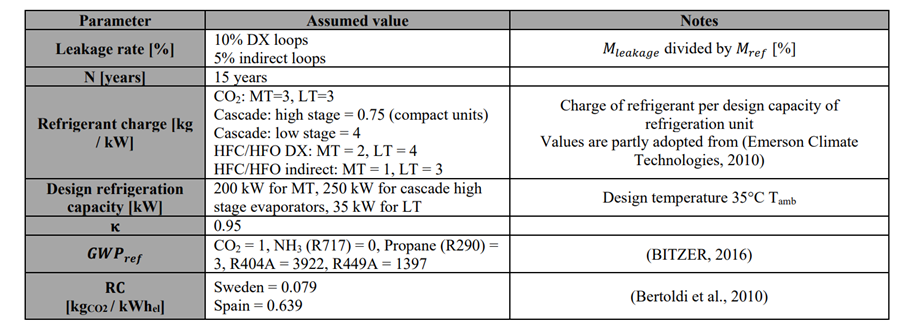

As can be seen from Table 1 observing the total equivalent warming impact (TEWI), a comparison is made between synthetic refrigerants, CO2 and NH3

Table 1 TEWI analysis assumptions

Source: Karampour, M., Sawalha, S. (2018)

This work by Karampour, M., Sawalha, S. (2018) looked at supermarket operation in Stockholm and Barcelona. Figure 1 clearly shows the high ambient significantly raises the electricity consumption but makes little difference to the leakage. However, note that they are not using sub-150 GWP R471, but rather R404A and R449A (many thousand GWP). The work therefore concludes that a state-of-the-art integrated CO2 system can meet the entire thermal demands of supermarkets efficiently in cold and warm climates.

Figure 1 TEWI comparison of supermarket systems in Stockholm and Barcelona

Source: Karampour, M., Sawalha, S. (2018)

Research by (Sánchez.D , et al 2018) focused on comparing a DX system of CO2 vs R134A operating at three heat rejection temperatures using a cabinet for fresh product as the cooling load. The results can be seen in Figure 2

Figure 2 – 24 hours total energy consumption of the refrigerating system.

Source: Sánchez.D , et al 2018

(Sánchez.D , et al 2018) concluded that for two DX systems running R134a and CO2 servicing a medium temperature cabinet with the same operating conditions at three different heat rejection temperatures (23.3, 32.7 and 43.7 ºC) and water as the secondary fluid, CO2 does not provide the same efficiency as the R134a-system. The difference can be clearly seen in figure 2. Adding a second internal heat exchanger, as illustrated, does reduce the difference significantly

Conclusion – is synthetic or natural best?

At the beginning of this article I mentioned simple economic supply and demand equilibrium. Economists use a phrase when drawing their curves ‘Ceteris Paribus’ which is Latin for with other conditions remaining the same or other things being equal.

That is where the OPEX discussion above needs reviewing from a different angle. It’s true that CO2 can, in some cases, match the energy consumption of synthetics, and it is without doubt cheaper, but that is today.

We know that to encourage carbon/CO2 abatement then the price for capturing CO2 must rise and with Carbon Capture and Storage (CCS) there is just cost, but for Carbon Capture Utilisation and Storage (CCUS) there is usage. So once many systems have changed to CO2, and demand is outstripping supply, which it already sometimes does in the summer months for AC and refrigeration, then with that comes price increases. The next factor to consider is just like the promise of lower bills after insulating your house and fitting a heat pump, you could wait 25 years to see payback.

Therefore as a supplier who is agnostic about the gas but wants to help industry down the path to Net Zero, new installations of CO2 make sense, but retrofitting before the end of life both in terms of CAPEX costs and CO2 wasted in scrapping equipment in the warmer regions of the UK seem less viable. The truth is rather like energy generation; we need a mix of solutions using both natural and synthetics where the greatest efficiency and lowest CO2e is emitted.

References:

Bruno, F.; Belusko, M.; Halawa, E. CO2 Refrigeration and Heat Pump Systems—A Comprehensive Review. Energies 2019, 12, 2959. https://doi.org/10.3390/en12152959

Dazhang Yang, Yang Li, Jing Xie, Jinfeng Wang, Research and application progress of transcritical CO2 refrigeration cycle system: a review, International Journal of Low-Carbon Technologies, Volume 17, 2022, Pages 245–256, https://doi.org/10.1093/ijlct/ctab086

Karampour, M., Sawalha, S. (2018) State-of-the-Art Integrated CO2 Refrigeration System for Supermarkets: a Comparative Analysis. International journal of refrigeration, 86: 239-257 https://doi.org/10.1016/j.ijrefrig.2017.11.006

Daniel Sánchez (a), Jesús Catalán-Gil (a), Rodrigo Llopis (a), Laura Nebot-Andrés (a) , Ramón Cabello (a), Enrique Torrella (a) CO2 vs. FLUORINATED REFRIGERANTS ENERGY EVALUATION IN A MT CABINET WITH DX-SYSTEM. 13th IIR Gustav Lorentzen Conference, Valencia, 2018 DOI: 10.18462/iir.gl.2018.1119

Antonijevic, Dragi. (2008). Carbon Dioxide as the Replacement for Synthetic Refrigerants in Mobile Air Conditioning. Journal of Thermal Science. 10.2298/TSCI0803055A.