12 November 2020

|

Daikin says the expansion of its circular economy programme will prevent 250,000kg of virgin refrigerant being produced yearly.

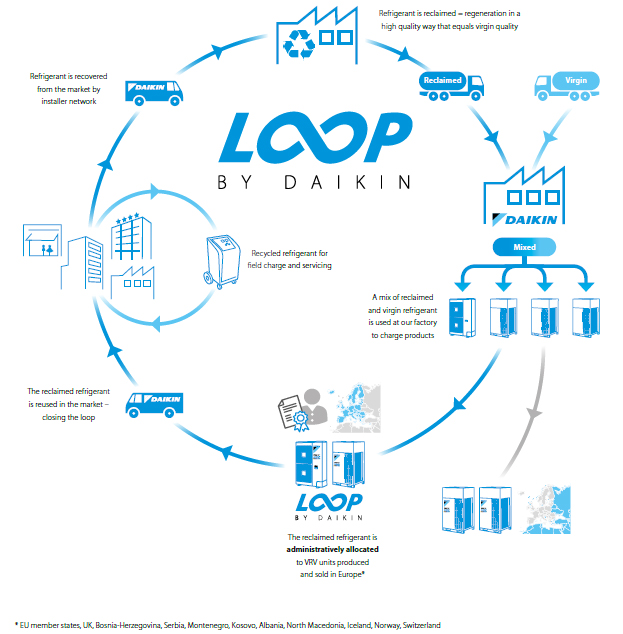

In 2019, Daikin UK introduced the use of reclaimed refrigerant allocated to VRV IV+ systems and VRV IV S-series units during production, as part of its Partner with Confidence programme. The initial quantity of reclaimed refrigerant allocated to these units avoided more than 300,000 tons of CO2eq from being generated in the production of virgin refrigerant.

Daikin Europe is now expanding its approach to all VRV units manufactured and sold across Europe from this month (November 2020) under the LooP by Daikin initiative.

The programme aims to save 250,000kg of virgin refrigerant from being produced yearly by giving access to recovered and reclaimed refrigerant. Independent certification guarantees that the reclaimed refrigerant fully meets quality standards and is correctly allocated to certified LooP by Daikin VRV units.

An independent audit process guarantees that the reclaimed refrigerant meets the exact same quality standards as virgin refrigerant. This process also ensures the correct administrative allocation of the reclaimed refrigerant: for every certified LooP by Daikin unit on the market, there is an equivalent 100% reclaimed refrigerant used at Daikin’s factories.

Daikin recovers refrigerants from existing systems through its installer network, upcycles and reclaims them to virgin quality, and then allocates the reclaimed refrigerants to new VRV systems manufactured and sold across Europe. Specifically, LooP by Daikin will now cover all EU member states, Albania, Bosnia-Herzegovina, Iceland, Kosovo, Montenegro, North Macedonia, Norway, Serbia, Switzerland, and the United Kingdom.

“LooP by Daikin is a perfect example of a circular economy,” says George Dimou, VRV product manager of Daikin Europe. “We work every day to make our products as energy-efficient as possible, improve the sustainability of our products and to motivate all of our partners and customers to join forces to reduce carbon emissions. The responsible use of materials is an integral part of this ambition. LooP by Daikin showcases just that. By eliminating resource depletion, we save tonnes of virgin refrigerant and reduce our impact on the environment.”

Daikin says it will continue to invest in its LooP by Daikin programme as part of its sustainable strategy. The company is committed to further expanding the programme in the short term to cover more types of refrigerants and different product ranges.

“We extend a hand to all of our partners, installers and customers to join forces and pave the way to a circular economy. By doing so, investing in reclaimed refrigerant boosts business and reduces our environmental impact. We believe the LooP by Daikin principle has the potential to become an industry standard, and will hopefully inspire other HVAC-R manufacturers,” said Toshitaka Tsubouchi, vice-president of Daikin Europe.