10 July 2025

|

Manuel Swärd, Export Director for West Europe at manufacturer IV Produkt, explains why an air handling unit solution specifically designed and optimised for heating is perfect for the UK climate.

As a result of the continuing drive towards improved energy efficiency and sustainability, alongside a strong focus on reducing investment costs and installation footprints, it is hardly surprising that UK customers are looking for new products and solutions to replace existing AHU HVAC installations for heating and cooling.

One of the key technologies available is the AHU with integrated reversible heat pump and, at first glance, it is easy to see the advantages of a much-simplified installation, only one heat exchange, and a ‘one-supplier, one-responsibility’ solution.

Traditional units over-promising and under-delivering

However, since most such systems traditionally are designed and optimised for cooling, they have largely promised far more than they could deliver, especially when it comes to energy efficiency and indoor climate during wintertime.

The ever-present defrosting issues and supply temperature fluctuations during colder weather have often forced suppliers and property owners to accept a number of design, operational and energy efficiency compromises.

Because no matter what design and defrosting technologies are applied, traditional units require either a decrease in the energy performance, adding substantial amounts of extra heating power and energy, or for the tenants to accept a deterioration of indoor air quality through significantly lower fresh airflows and much lower supply air temperatures in winter.

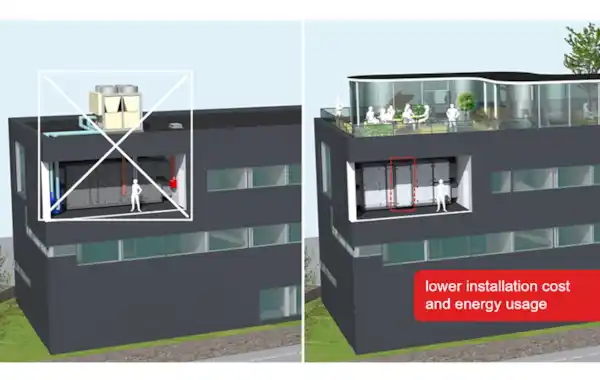

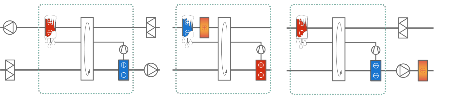

Operational challenges and different defrosting techniques when running traditionally designed reversible heat-pumps in wintertime (a) Typical integrated HP design with one heat exchanger positioned on the ‘cold’ side of the thermal wheel operating in reverse cycle defrost with reduced capacity and airflow. (b) Close proximity electric heaters used to defrost the frozen evaporator (c) reheaters used to increase supply air temperature during decreased recovery and reverse cycle defrost.

The UK focus on improved and hygienic indoor climate, energy efficiency, decarbonisation and overall sustainability means that these compromises are no longer acceptable, with another type of reversible unit needed. This resulted in IV Produkt developing and launching a completely new type of defrosting-free AHU with integrated reversible heat pump, the Envistar Flex ThermoCooler HP R454B.

ThermoCooler HP R454B

ThermoCooler HP R454B is specifically designed with defrosting-free heating applications in mind, while still providing effective and efficient cooling operation.

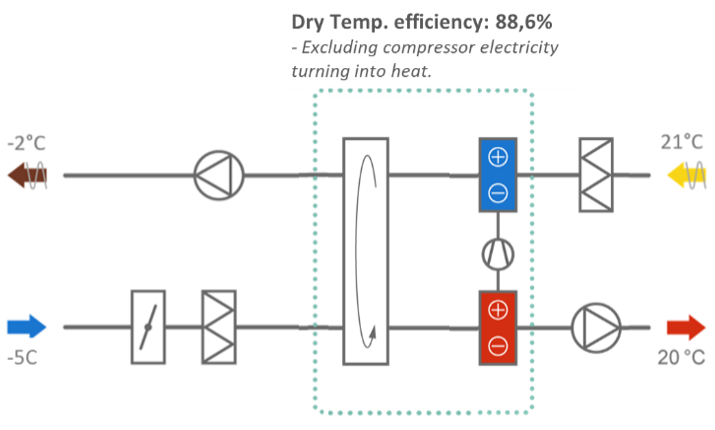

The new DX-cycle design and AHU-layout, with both the evaporator and condenser positioned on the ‘warm’ side of the thermal wheel, is a perfectly optimised design for the UK and northern European climate, where uninterrupted heating operation in winter, without any defrosting, pre-heating or re-heating needs, far outweighs maximum cooling power in fresh air ventilation AHUs.

Performance flowchart in heating mode of the ThermoCooler HP defrosting free reversible heat pump unit

In heating mode, the new DX coil positioning enables a control algorithm that always maximises the temperature efficiency of the thermal wheel and only uses the heat pump to top up the supply air temperature when needed, something that significantly increases the unit’s Seasonal Coefficient of Performance (SCOP).

In cooling mode, fresh air free cooling and night cooling are always prioritised before the DX cooling is activated. This fresh air operational sequence, together with the ThermoCooler HP’s new higher DX evaporation temperatures, reduces the unit’s latent cooling power and energy consumption, and provides pleasant cooling comfort with the lowest possible energy input.

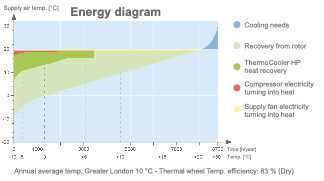

Energy efficient operation

The diagram above illustrates how the thermal wheel and the reversible heat pump first work in sequence at higher ambient temperatures, and then start working in parallel when the thermal wheel alone cannot provide 20°C supply air. This example is taken in a Greater London climate with an annual average temperature of 10°C.

Improved sustainability and 3 out of 3 available BREAAM credits

As the UK market also drives towards lower GWPs and higher sustainability, the new product has been designed to operate with R454B refrigerant, which significantly lowers the relative heat pump GWP by 78% and 31%, respectively, when compared to R410A and R32 machines.

BREEAM is a widely-recognised third-party certification system used to specify and measure the sustainability performance of buildings. The new R454B DX cycle design, smart volume versus power ratio and integrated automatic leak detection system means ThermoCooler HP R454B qualifies for all 3 out of 3 available BREEAM credits under Pol 01, Impact of Refrigerants, a unique achievement from an AHU with integrated reversible heat pump.

Customer simplification and full security

Since making life as simple as possible for our customers is a key objective for IV Produkt, the ThermoCooler HP R454B units are delivered factory-tested, CE-marked, and with a Declaration of Conformity, certifying that the units comply with all relevant European regulation and industrial standards. This means that customers can install the units in normal plant rooms through the CE marking, without further risk assessments for concerns such as. A2L refrigerants

The integrated automatic leak detection system is always fully operational and will automatically start the AHU and bring any refrigerant concentrations down to completely harmless levels, even in the case of a total failure where all the refrigerants may have leaked out. This safety function overrides all other operating modes, even if the unit is shut off for the night or being held off by a building management system.

Crucially, ThermoCooler HP R454B also has ISO Environmental Product Declarations (EPDs) for embodied carbon.

Save investment cost and avoid operational problems – use correct design data!

No matter what technologies are used to generate comfort cooling, there are significant investment costs to be saved, as well as lots of operational stability and flexibility to be gained, by using the correct cooling design data.

Since comfort cooling is there to provide a comfortable indoor climate, it is easy to understand why cooling design criteria is often over-exaggerated and put into specifications. However, this well-intentioned safety margin doesn’t only risk increasing overall investment costs, it can also significantly reduce your operational stability and variable air volume (VAV) flexibility during part load.

Warmer temperatures: lower relative humidity [RH]

One of the most common mistakes when specifying design criteria for cooling is the incorrect assumption that maximum temperatures and maximum relative humidity occur at the same time, while they in fact are mirroring each other.

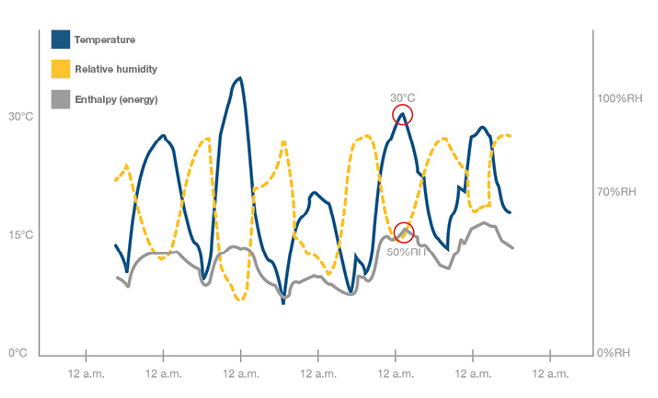

The graph below from a warm summer week in Greater London 2024 shows that even if both the temperatures and the relative humidities at times were higher, a design criteria of 30°C/50% RH would in fact handle the enthalpy needs for all actual design conditions.

Consider this: If you design to cool 1m3/s of outdoor air down to 16°C, and you change design criteria from 30°C/50% to the seemingly only slightly higher design criteria of 32°C/60% - you will need to invest in almost 55% bigger cooling capacity.

With a 55% oversized cooling capacity, you will naturally face problems with operational stability and temperature control during your lower part-load operation, and in fact, the vast majority of all running hours for comfort cooling are part-load, so it is best to design systems to the correct cooling design data!

Entahlpy profile on a day in London with temperature and RH relationship