18 April 2019

|

| John Grenville, managing director of ECEX, offers practical maintenance advice for HVAC equipment. The London Olympics in 2012 saw Team GB cyclists win an impressive seven gold medals; the rest of the world won just three. This outstanding British sporting achievement was made possible because of a man called Matt Parker (now director of performance innovation at the English Institute of Sport). |

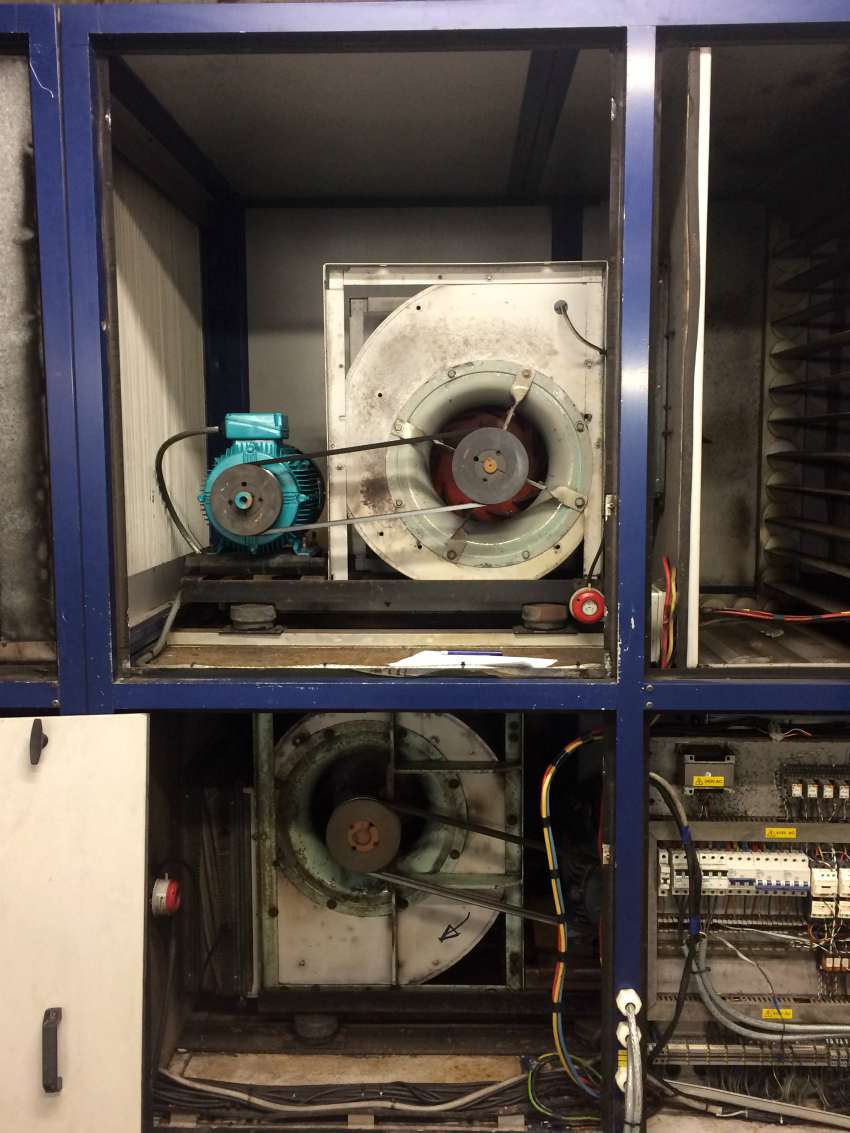

| He came up with lots of small ideas that, together, boosted the cycling team’s performance significantly. One of his ideas was heated pants worn by the athletes to keep their muscles warm as they waited to start a race. Another was rubbing alcohol on the bikes’ tyres before a race to clean off dust and give them more grip. Parker’s job title at British Cycling during the 2012 Olympics was head of marginal gains. The notion of taking a complex process, breaking it down and making small changes to boost performance clearly works and the big impact of small steps should not be underestimated, especially when it comes to maintenance. By keeping on top of coil and filter maintenance, for example, striking savings in energy can be achieved and expensive repairs and breakdowns can be avoided. Indeed, that’s why it is a false economy to underfund HVAC maintenance; the knock-on effects of doing things properly should more than pay for the cost, particularly for buildings where large amounts of energy are being wasted. Attractive savings And effective maintenance and refurbishment can actually improve (rather than simply sustain) an aging HVAC system’s performance. An effectively implemented maintenance plan can add to the bottom line by ensuring that HVAC equipment is energy efficient and therefore produces lower fuel bills and higher environmental performance. In short, implementing maintenance effectively pays real dividends in terms of fewer breakdowns, better efficiency and healthier profits. Fan replacement in air handling units (AHUs) can improve operational efficiency by more than 30% in some instances so it is clear that the cumulative effect of upgrades/repairs can have a big impact on cost and efficiency. However, maintenance and refurbishment are not the be all and end all – applying relatively simple measures can mitigate against the need for it in the first place. For example, my own company’s ECEX Air Intake Screens – effectively external filters fitted to equipment such as AHUs to prevent airborne debris entering and affecting their efficiency – have been proven to reduce environmental impact and servicing requirements significantly, as well as making attractive cost and energy savings. They also prevent damage caused by power washing or the use of harsh/aggressive treatment chemicals, reduce coil treatment and cleaning costs, reduce downtime and extend the serviceable life of HVAC plant. An independent trial at Westminster City Hall in London measured the benefits of ECEX Air Intake Screens. Two AHUs were chosen for the trial in the 20-story building. Monitoring equipment was installed for the duration of the trial on the supply fan motors on each AHU with pre-heat, supply air temperature and outside air temperatures also scrutinised. The AHUs were monitored in the first stage without the Air Intake Screens installed running under normal conditions. Primary and secondary filters were then replaced, and Air Intake Screens were installed across the air opening on both AHUs. Monitoring began again and, during this second stage of the trial, the screens were brushed down by the maintenance staff. Planned maintenance The results were remarkable. For example, on CO2 emissions, the two trial AHUs clocked up savings of 438kg and there was also a 4.9% reduction in power consumed. The site’s M&E manager noted: “Following the installation of the Air Intake Screens, we will achieve CO2 emission savings from just these two AHUs of over 5,000kg per annum, equivalent to taking one car off the road for a whole year.” So, mitigation measures can help. Other useful maintenance practices include keeping a daily operating log and compare the recorded performance with design and start-up data. An accurate log offers a daily snapshot of the equipment’s operating characteristics, making abnormal conditions easier to spot and rectify. Check for leaks and moisture ingress. After all, it has been estimated that that 1psi of air in a condenser equates to a 3% loss in chiller efficiency. Moisture in a chiller can create acid which will corrode motor windings and bearings, resulting in rust forming inside the shell. Treat water with appropriate chemicals to reduce scale and corrosion and prevent biological growth. And, remember to clean the system. HVAC equipment performance is dictated by its ability to transfer heat and that starts with clean coils and fans. Cleaning and changing filters as part of a planned maintenance programme can reduce the likelihood of equipment failure and boost the energy efficiency of the equipment. ECEX has launched a free, wide-ranging guide to HVAC system maintenance. HVAC System Maintenance, a guide to effective equipment servicing, explains the steps to maintenance good practice, including how to draw up a maintenance policy, developing a maintenance strategy, details of different forms of maintenance and assessing maintenance needs. www.ecex.co.uk |

Content continues after advertisements