17 April 2019

|

| What does the future hold for companies operating in the HVAC sector? Christian Rudio, Europe HVAC portfolio director at Johnson Controls, looks at five major trends. Growing concerns about climate change have led to a greater awareness of the need to reduce energy consumption, from household appliances to commercial and industrial HVAC systems. |

|

Impact on installers The five trends identified in the main article will also have a dramatic impact on installers. For example:

|

As sustainability moves rapidly up the environmental agenda, so the HVAC industry has started to rethink the technology and service it offers. HVAC equipment manufacturers no longer offer just a product, but a total package including advice on capacity, redundancy and, of course, sustainability.

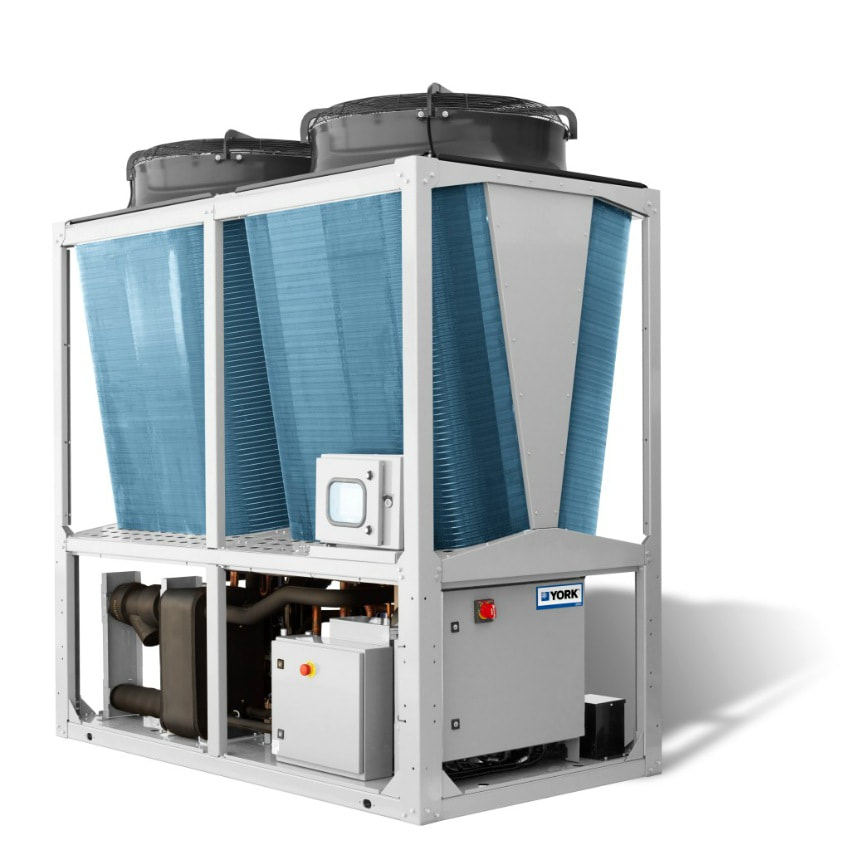

There are, in my view, five major trends that will impact on how the HVAC sector responds in 2019. They are: 1. Rethinking refrigerants The EU’s F-Gas regulation is accelerating the phase-down of HFC (hydro-fluorocarbon) refrigerants in favour of environmentally friendly equipment with no ozone depletion potential (ODP). In recent years, the HVAC industry has invested heavily in the development of products using next-generation refrigerants and this trend is set to continue in 2019. So far, only a few recently developed refrigerants have been classified as non-flammable. In fact, next-generation refrigerants classified as being mildly flammable can be used safely, but some building owners may have concerns about using them. Hence, we can expect greater awareness and training on the use of mildly flammable refrigerants, as well as continued research into non-flammable alternatives. 2. Shift to Ecodesign Since last year, the Ecodesign Directive has applied to HVAC products in the European market. The directive obliges the sector to address the environmental impact of their products from the earliest stages of the design. In 2021, the next tier of Ecodesign – so-called Ecodesign Tier 2 – takes effect. It will It will tighten requirements further and make obsolete many existing products. As a result, optimizing equipment design and selection to improve the total annual energy use will become increasingly important for both equipment and project designers. Many YORK products already comply with Ecodesign Tier 2 regulations three years early and offer significantly better energy efficiency than required, resulting in an attractive, low-cost operation and lighter environmental footprint. 3. Energy audits HVAC systems still account for around half of a building’s energy consumption. Building owners should no longer be satisfied with just the energy performance rating value of a product, but ask for a complete energy use analysis, including the consideration of operating hours and weather data. These energy audits are easy to generate with computer rating software and allow owners to make the most informed decisions about how to allocate capital to best optimize energy use and operating costs. Retro-commissioning, the process of identifying and enhancing less-than-optimal performance in a facility, is still booming. This process focuses on improving the efficiency of installed HVAC systems through monitoring how the building is used and making simple improvements of existing equipment control sequences and other minor upgrades, helping to achieve significant energy savings without large investment in new equipment. 4. Modular systems Modular chiller and heat pump systems are already common in Asia, but we are now starting to see a growing demand for these systems in Europe too. Advances in variable speed compressors, improvements in heat transfer surfaces and software controls have made this type of equipment able to achieve very high efficiency without adding much cost. A system combining several modular chillers or heat pumps is easier to install. The equipment can be fit in a service lift or crane already on site, while separate modules can be arranged to fit in tight spaces, so capacity can be added without structural renovations. A central controller allows the modules to work together as one and the building control systems don’t have to change. Furthermore, multiple heat pump modules can be sequenced so only one circuit goes into defrost at a time, allowing a better control of the heating setpoint and maximum reliability. 5. Absorption chillers For larger installations and heat recovery, we see a growing demand for absorption chillers. They use a heat source to drive the unit and provide cooling through a chemical process between water and a lithium-bromide solution. Absorption chillers are increasingly replacing regular electrical driven compressors in industrial applications where a large amount of heat is available to be recovered, which before was usually wasted to ambient. Absorption chillers are being applied in medium applications too, such as shopping malls, schools and hospitals. A recent trend is the use of absorption chillers in large municipalities where excess heat coming from the district heating grid in summer can be re-used by the municipalities to provide district cooling. YORK’s absorption chillers and heat pumps use an innovative evaporator and absorber design that splits the absorption cooling process into the so called ‘two-step’ system. This results in reduced lithium-bromide concentrations and overall increased efficiency which allows both a downsizing of the unit and reduced cost of ownership. Also, the water used in the heat source is a natural refrigerant, so YORK absorption systems are environmentally-friendly too. www.york.com |

Content continues after advertisements