21 June 2017

|

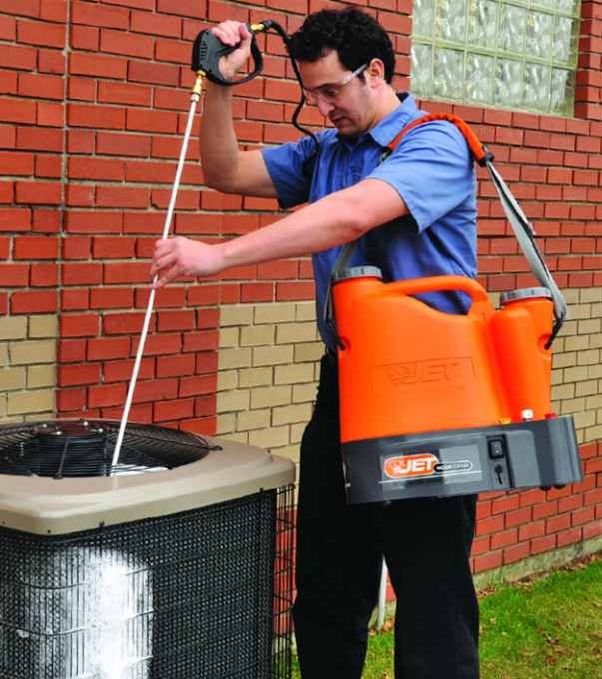

| As the temperature rises, residential and light commercial HVAC maintenance company SpeedClean explains why the correct cleaning regime can deliver major benefits. Cleaning coils is smart for businesses because it can help ensure that systems perform properly throughout the season and without consuming excessive amounts of energy. When coils are not cleaned regularly, particles build up in between, which makes the air handler work harder and the heat exchange process less efficient. Industry-leaders state that preventative maintenance practices, such as regular coil cleanings, are key to keep equipment running at their peak efficiency, save energy and decrease the likelihood of system failures, potentially extending the life of the HVAC system. |

Dirty coils also negatively impact Indoor Air Quality. When dirt, dust and pollen are clogging the coils, more of these particles are let out into the home or office along with the cooled air. Uncleaned coils also promote the growth of bacteria, mould spores and other unhealthy organisms that can produce bad odours, allergies and generally contaminate the air.

What steps should contractors take to clean condenser and air handler coils?

SpeedClean’s coil cleaning checklist will help ensure HVAC technicians and contractors have taken all the necessary steps to properly clean a building or office’s condenser or air handler coils. Some items on the list include:

SpeedClean carries a variety of coil cleaning equipment which is simple to use and can be operated by one person. The CoilJet CJ-125 cleans coils without damaging sensitive fins, even in hard-to-reach areas. For mini-split systems, the Mini-Split Bib Kit makes cleaning quick and mess-free.

www.speedclean.uk.com

What steps should contractors take to clean condenser and air handler coils?

SpeedClean’s coil cleaning checklist will help ensure HVAC technicians and contractors have taken all the necessary steps to properly clean a building or office’s condenser or air handler coils. Some items on the list include:

- Inspect and clean mini split ductless systems at least annually. For greater efficiency, check mini split systems between seasons – once in the autumn and once in the spring. Inspections should include checking filters, coils and blower wheels for dirt buildup.

- Avoid cleaning coils using compressed air or nitrogen. This blows dirt and debris into the air, creating IAQ problems and possibly recontaminating the coil and blower wheels that were just cleared. It also displaces any mould spores, which can create health problems and further mould issues if not properly managed.

- Use pressurised water. This is the best way to flush dirt and debris and thoroughly clean the coils, using limited chemicals. Consider using a portable, battery operated coil cleaning system like the CoilJet CJ-125 for cleaning coils and blower wheels.

- Protect walls and floors during the coil cleaning. Condensate lines generally don’t do a good job of moving a lot of water. Using a bib system, such as the Mini Split Bib® Kit, will safely capture excess water and cleaner and protect walls, floors and furniture from overspray.

- Treat coils to prevent “dirty sock syndrome.” Apply an EPA-registered mould and mildew inhibitor to protect against odour-causing bacteria for months at a time. Make sure the chemical is safe to apply while the space is occupied, like Mould Control from BBJ.

- Don’t forget about the condenser coils. Dirty condenser coils can drive up the ductless system’s heating and cooling costs. Make sure to clean condenser coils with pressurised water every time indoor coils are cleaned.

SpeedClean carries a variety of coil cleaning equipment which is simple to use and can be operated by one person. The CoilJet CJ-125 cleans coils without damaging sensitive fins, even in hard-to-reach areas. For mini-split systems, the Mini-Split Bib Kit makes cleaning quick and mess-free.

www.speedclean.uk.com

Content continues after advertisements