18 April 2019

|

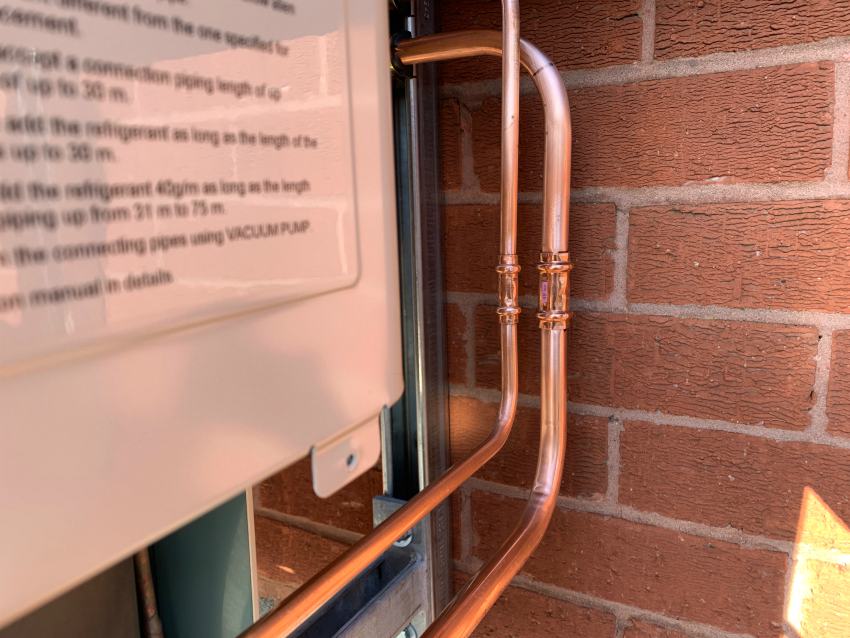

| Among the locations where an air conditioning system needs to perform effectively and be reliable is the potentially hot environment of a busy nightclub. When Aircool Technology was commissioned to fit a new air conditioning system at the Fever Clubrooms in Nuneaton, the installer chose Conex Bänninger’s >B< MaxiPro press fittings as the pipework jointing solution. |

| “Using press, instead of brazing or solder, makes the job so much easier and the time saved is a major benefit,” said Aircool director Alex Negrescu. As >B< MaxiPro is a flame-free joint there is no requirement for a hot works permit and the risk of fire on site is eliminated. Aircool Technology specified a total of four Toshiba 14kW ceiling mounted cassette systems, two in the upgraded Fever room and two in the extended Zinc room, as part of a major refurbishment towards the end of 2018. Pressure tested These were coupled with energy efficient Toshiba Super Digital Inverters for heating and cooling and which are suitable for light commercial projects and provide the opportunity for longer pipe runs. Negrescu added: “The pipework for the Fever room extended to 20 metres each system, while for the bigger Zinc room it ran to 35 metres each system. “We used >B< MaxiPro fittings all the way, with no brazing joints and on completion of the installation each system was pressure tested up to 40 bar. “In nightclubs there is often lots of furniture and equipment. If you make the smallest mistake things can go wrong. However, by using the press tool we do not have to worry.” >B< MaxiPro was specially designed and engineered to handle the higher operating pressures required for air conditioning and refrigeration installations, up to a maximum 48 bar, with a permanent maximum operating temperature range of -40°C to 121°C. As a mechanical joint there is no need for a nitrogen purge during the jointing process. It also has the benefit of a 3-point press, with one press each side of the bead and a third compressing the HNBR O-ring, providing a secure, leak-free joint. Simple process Negrescu added: “We have worked with press for a while, but that was with a different system. It was good but we’ve found >B< MaxiPro even better. Unlike other systems, once you have the press tool and relevant jaws you don’t need any additional kit. “It makes completing the joint such an easy job, with no messing about. It’s very quick and the time saved helps us to be more productive as a business. For the Fever nightclub I had other guys working with me but I was able to complete all the >B< MaxiPro joints on my own. “I undertook the training with technical sales manager, Zoheb Khamker. He was right about the simplicity of the process – measure the pipe, cut and clean it making sure there are no cuts or scratches, mark it to the correct depth and, having inserted the pipe into the fitting to the correct depth, press it. “As soon as you have done the first one correctly, that’s it.” Aircool Technology is based in Gloucester and operates across the wider West Midlands. It offers complete air conditioning management, from the initial design stage through to commissioning and final testing. Aircool has also used >B< MaxiPro for an air conditioning installation for a new hotel in Canterbury, with the system tested up to 45 bar. www.conexbanninger.com |

Content continues after advertisements