16 August 2022

|

PHIL CREANEY’S ACR CHAMPION

Sponsored by ACR Journal

John Emm

This special award recognises a 58-year career in the industry which began with an engineering apprenticeship in 1964.

After many years as a service, maintenance, and installation engineer, he moved into sales, quickly becoming regional sales manager, and then promoted to branch manager for Dean and Wood (London).

John bounced back from a major stroke in 2009 and, in addition to his day job at Pumps2Go, has remained a driving force behind the Hampshire Refrigeration Society even though he now lives in Cheshire. He has played a key role in organising one of the biggest golf tournaments in the industry calendar and the popular HRS breakfast briefings, and recently revived the society’s regional trade show.

After eight years he travelled to Saudi Arabia to work for Refrigeration House, a major wholesaler with six branches. As general manager/CEO he was also responsible for overseeing the joint-venture of a manufacturing company of grilles, diffusers, and other ventilating equipment. Across the group, he was responsible for nearly 2,000 workers including sales engineers, project managers, O&M engineers, and production personnel etc.

On his return to the UK, he joined Dawmec, the Copeland compressor distributor, eventually becoming MD, before leaving to set up his own pack-building company Enetech Products.

In 2015 he was appointed the distribution agent for SICCOM condensate pumps and sensors. This is when he formed Pumps2Go, providing pumps and other RAC accessories and products to major wholesalers and contractors in the UK and Ireland. In April 2022 P2G Ltd was acquired by the Strut Foot Group and has been retained by the new owners as technical director.

John has been a member of several industry societies, institutions and associations and is a past chairman of the Equipment & Components Section of the BRA-FETA . He was also chairman of the IOR membership committee and has sat on the council.

ACR ANCILLARY PRODUCT

Sponsored by REFCOM

Winner

Digital Network (BITZER)

The new BITZER Digital Network (BDN) is designed to open up almost infinite possibilities for improving refrigeration system performance, reducing running and servicing costs, and minimising the impact of cooling systems on the environment.

The latest intelligent compressors – and the networks they are part of – give direct access to both real time and historical data, which opens up huge opportunities to improve performance, minimise costs and reduce environmental impact. The new digital infrastructure, the foundation for this revolution, is now being put in place. At its heart are intelligent compressors and refrigeration systems connected into a higher level network for monitoring and sophisticated data analysis. It is at this supervisory level, which gives rapid access to the wealth of data and insights, that the power and potential of digital services comes into play.

Each unit can be registered and viewed on a customer’s accounts via myBITZER. For each unit it shows compressor status, operating temperatures and pressures, diagnostics, and any warnings and alarms. There is no need to export data to another programme. Users simply log into their account and run a report from inside the BDN. This can be customised in multiple ways to zero-in on particular issues, and over various time-frames. BDN brings together the company’s in-depth product and application knowledge with real-time intelligence and data from working systems.

This is used to provide customers with actionable insights that can be used to improve all aspects of system performance. It also gives access to the latest technical information relevant to compressors and components in systems. This includes everything from an electronic parts database, online documentation and software, in addition to compressor monitoring and advanced analysis. Through predictive analysis and genuinely intelligent preventive maintenance, BDN enables us to pre-empt issues, dramatically increasing reliability and minimising downtime.

Highly Commended

VRF Controller PC-ARFG-E (Hitachi Air Conditioning UK & Ireland)

Launched in January 2022, this controller is suitable for all Hitachi VRF applications, including hotel mode which incorporates a special display for hospitality venues, instant access to the most demanding functions by hotel guests, easy reset for housekeeping service, and a feature which allows the controller to be connected to guest room card key locks, enabling energy saving during room vacancy.

Improvements from the previous model include:

- Temperature setting with 0.5°C step

- Comfort function (Gentlecool and others)

- Comfort or energy saving functions relating to a motion sensor

- Power saving modes

ACR CONTRACTOR

Sponsored by Fujitsu

Winner

Cross Group

The origins of Cross Group date back to the mid-19th century and to the centre of Cork city – where two members of the Cross family started a carriage hire and stables business. During the 1920s, Cross’s Garage Ltd extended their business extended to the sale of ice boxes and mechanical domestic refrigeration. And so began the long association with refrigeration.

In 1966, Cross was appointed Frigidare distributors for Ireland and decided to separate the refrigeration business from the garage. This led to the formation of what is now Cross Refrigeration. In 1968, the business was acquired from the Cross family and made the move fully into commercial refrigeration – a staple of the business to the present. The group of companies has developed into a young, diversified and dynamic enterprise with interests in multiple sectors. The core of the business remains refrigeration, but its presence is being successfully felt in a number of related sectors too. Today, the enlarged Cross Group brings in an annual turnover of £66 million – and that growth looks set to continue.

A progressive drive for innovation, embracing new ideas, technology and concepts, has helped it remain competitive and win new projects and customers across four continents. Much of the innovation is driven by the need for efficiencies, whether it be reductions in energy, carbon, labour or space. The latest innovation and step-change in efficiency is the construction of the world’s first automated banana ripening facility at DP World, London Gateway. The project for Compagnie Fruitiere, brings temperature controlled fruit ripening to a whole new level, with substantial reductions in energy, manpower and wastage.

Cross Group is proud to introduce automation it into the global fruit ripening sector, delivering reliability, efficiency and reduced costs to its customer, and keeping it ahead of its competitors.

Highly Commended

Energie Solutions

Energie Solutions is a customer-focused renewable energy company covering East Anglia and London. It aims to deliver Expert Solutions for a Sustainable World.

Established in 2012, Energie Solutions is an approved installer for Daikin, Mitsubishi Electric and NIBE.

The company originally provided a complete heating system for a customer in Lowestoft under the Suffolk Heating Schemes project, designed to help vulnerable people and their families make their homes cheaper to heat. Replacing outdated Economy 7 storage radiators, Energie Solutions designed a new system including upgraded radiators, a 200l pre-plumbed cylinder and 7kW Daikin Altherma air source heat pump.

Energie Solutions has continued to service the system and subsequently installed a solar thermal system, including cylinder, which now produced much of the family’s hot water. The customer is now looking to install solar PV to further reduce his bills and carbon footprint.

ACR PRODUCT

Sponsored by Blygold

Winner

Etherea with nanoe X Technology (Panasonic)

Panasonic’s latest range of Etherea units are designed to suit a wide range of interiors with a new collection of colours and in a slim profile. The units achieve the highest energy ranking of A+++ in heating and cooling and boast super quiet noise operation. The units also utilise Panasonic’s R32 Inverter Compressor for a lower environmental impact.

The smart Etherea unit also comes with nanoe X technology built in, bringing the benefits of hydroxyl radicals indoors so that hard surfaces, soft furnishings, and the indoor environment can be a cleaner and pleasant place to be. Abundant in nature, and active in the air and on surfaces, hydroxyl radicals have the capacity to inhibit five types of pollutants, including certain viruses and bacteria as well as odours to clean and deodorise.

Independent tests carried out in July 2020 and November 2021 confirmed the inhibitory effect of nanoe technology - 99.8% effective against the adhered novel coronavirus Delta variant (SARS-CoV-2).

Panasonic strives to create a comfortable environment for homeowners, which has led to the Etherea range featuring Aerowings 2.0, two independent flexible vanes that concentrate airflow to heat or cool a room in the shortest time possible and help distribute air evenly throughout a room.

The Etherea units come with built-in Wi-Fi which enables advanced smart control and voice assistant. The units can pair with Panasonic’s Comfort Cloud app which is specially designed to easily manage all system functions via a smart device.

The range is available in single and multi-split. Single split systems require one indoor and outdoor unit, whereas the multi-split range is suitable for applications where air conditioning requirements exceed a single room, allowing up to five indoor units to be connected to a single outdoor unit.

The Etherea line-up is suitable for residential homes, retail and commercial applications such as healthcare, offices and hospitality spaces with a wide range of capacities from 2kW – 3.5kW.

Highly Commended

HAORI (Toshiba)

Toshiba's new HAORI residential indoor split unit is a fresh take on the industry's conventional approach to air conditioning. It is designed to become an elegant part of a home's furnishings, and prove that home comfort technology can fit in beautifully.

The unit has a textile cover available in a range of standard and optional colours, and also offers infinite customisation possibilities by using fabric from a home's own furnishing or curtains. Using a supplied fabric pattern kit, HAORI owners simply take their chosen design to a tailor or, if they can sew, make their own.

The visual appeal is matched by technical excellence and energy efficiency. Best-in-class performance is underpinned by triple A efficiency (for both heating and cooling), near-silent operation and market-leading air quality. Based on R32 refrigerant for reduced environmental impact, HAORI’s A+++ energy performance provides the best part-load efficiencies in its segment. The system is rated to 8.6 for SEER (Seasonal Energy Efficiency Ratio) and 5.1 for SCOP (Seasonal Coefficient of Performance).

ACR PROJECT

Sponsored by HRP

Winner

Compressor Replacements (GEA Heating & Refrigeration Technologies)

GEA Refrigeration (Leeds) and several other providers were given the opportunity to look at a service project to upgrade the controls and carry out the service exchange of seven compressors packages across five refrigeration plant rooms to increase reliability of a refrigeration plant.

Instead of doing a remedial service task, GEA took the opportunity to provide an efficient, reliable and future proof proposal that would not only benefit the customer financially but also improve the environment by reducing the site’s electrical consumption and cutting CO₂ emissions.

When the client gave the go-ahead, GEA carried out the replacement of the compressor packages and replaced the controller with a new OMNI controller.

GEA also carried out the installation of Danfoss VSDs to the compressor drive motors, allowing for fine tuning of the operating conditions of the compressors and saving further energy.

Unique features of the project were the introduction of inverter control, OMNI controller, high efficiency motors and GEA’s latest compressor technology.

Calculations show a potential energy saving of £213,650/annum based on two compressors being fitted with inverter drives. The figures assume the same loading from existing profile to the new profile and assume the existing compressor is running at maximum efficiency. The potential energy savings are not only made up from the inverter savings but also from the efficiency of the compressor.

The customer said the reason for GEA being award this project was due to their “outside thinking approach, looking at the bigger picture in terms of our utilities usage and protecting the business thinking. Yes, we have had to invest further capital on this project but alongside the savings GEA have proposed, this makes it a no-brainer.”

The project was carried out in three phases. Phase 1 was to remove the existing packages and install double block and bleed isolation on all services; phase 2 was to locate the compressor package, carry out the pipework and electrical installations; phase 3 was to commission the packages including pressure test, leak test and bring online to suit site requirements.

Highly Commended

22 Bishopsgate (Carrier and Michael J Lonsdale)

The building is 62 storeys with 1.275 million square feet of residential, office and indoor amenity space with a Building Research Environmental Assessment Method (BREEAM) rating of Excellent. The developers are also currently pursuing certification under the WELL Building Standard. These standards required the highest levels of energy efficiency and environmental performance.

A major challenge on the project arose from the fact that the building’s foundations and basement plant rooms were originally designed for a different building project, with a smaller overall floor space. As a result, the building’s foundations had to be adapted, to accommodate the building services plant required to support the larger building.

The Carrier solution is based on four AquaEdge® 19XRV high-efficiency centrifugal liquid chillers, each delivering 4MW of cooling with efficiency levels as high as 6.8 European Efficiency Rating (EER). The chillers are equipped with Greenspeed Intelligence variable speed drives, which constantly match cooling output to the building’s heat load, optimising comfort, reducing energy consumption and minimising impact on the environment.

ACR TRAINEE OF THE YEAR

Sponsored by Beijer Ref Academy

Winner

Gemma Weston (J&E Hall)

Gemma Weston joined J & E Hall last year with a glowing reputation which has proved to be well deserved.

Service supervisor Phil Dynes says: “Gemma’s enthusiasm and drive is something that sets her apart. She is confident with customers, suppliers and colleagues and has a willingness to learn and quickly take on board new skills.

“Gemma embraces the challenges the job can bring, tackling issues methodically and never letting them overcome her. She has a positive attitude to solving problems and tasks given to her. Gemma is not afraid to ask questions and works well with other engineers to understand where she can improve and develop.

“Gemma has only been with the company for a short time but is already proving to be a valued member of the team. She has developed a significant level of practical experience which supplements and enhances the knowledge she is gaining through her college course. On a recent site visit, one customer highlighted Gemma’s capabilities and specifically acknowledged her as a hardworking and valued member of the team.’’

Gemma, who is also studying at Eastleigh College said: “I was never going to be the person to wear heels to work, steel capped safety boots were always going to be my choice of footwear and it came as no surprise to my family and friends when I decided to join the industry. When an opportunity arose for an apprenticeship in a service role I knew the position was for me. The structured discipline where I could do onsite training and gain a qualification was exactly what I needed.’’

As a student member of the IOR, Gemma has taken part in many webinars and appeared in articles offering her thoughts and experiences on apprenticeships and women in the RACHP industry. She has joined the IOR group promoting STEM as well as being active outside the industry by celebrating International Women in Engineering Day. She has also joined the committee for the WiRACHP steering group.

Runner-up

Jordan Guy (GEA)

Jordan Guy is described as “an absolute credit’’ to GEA HRT, acting as an ambassador for the business and ensuring its reputation in the industry is maintained.

He joined as an apprentice working at the Leeds branch after previously working in the engineering team at Quorn Foods.

His nomination from GEA reads: “In 2020, we had the opportunity to recruit an industrial refrigeration apprentice. Over 100 applications were received and Jordan stood head and shoulders above the other applicants. From our very first encounter, Jordan stood out as bright, enthusiastic, and diligent, with a keen interest in furthering his knowledge of refrigeration and building himself a career in the industry.

Mark Denford, senior trainer consultant at Grimsby Institute, said: “Jordan is currently on his second block in year 2 of his 6090-50 level 3 Eng Tech standard, and from day one has committed himself to his apprenticeship. His thirst for knowledge and attitude is outstanding and he is more than happy to help other students if they are struggling. Jordan works on industrial ammonia systems which are complex, and this does not seem to phase him at all.’’

Highly Commended

Josh Eames (SURE Solutions)

Josh Eames has set a high bar for himself since joining SURE Solutions and is very passionate about taking ownership of his own development. His performance on the job is said to be exemplary, and he is always asking questions to build his knowledge.

His employers say he only needs to be shown something once, then he's away with the task and can support the senior engineer on site. He has high standards of work, as evidenced by winning the scrapheap challenge at Grimsby Institute and the level of his welding skills given the short period.

Craig Shaw of SURE said: “Josh has progressed very quickly in his time with us. He is naturally curious and puts this to practice in seeking to understand the systems he is working on and progressing his knowledge more generally. Josh takes ownership of his own development and is constantly putting his hand up for training courses to widen his knowledge and experience.’’

AIR SOURCE PROJECT

Sponsored by BITZER

Winner

Grange Barn (UK Alternative Energy and Secon Renewables)

Grange Barn is a 311 m2 luxury 4-bedroom home located at Billinghay, Lincolnshire. In 2020, developer Ash Country Homes acquired the site to convert the former agricultural building into an environmentally friendly home with low operation costs. UK Alternative Energy teamed up with Sunderland-based renewable specialist distributor Secon to design and deliver the project.

The Panasonic T-Cap Monobloc was the standout favourite for this project. It is designed to offer high leaving water temperatures with no loss in capacity to -15°C ambient temperature and no requirement for bivalent heat sources until -20°C.

Using SAP 10.1 data for energy profiling and the Panasonic T Cap Seasonal coefficient of performance, a system was designed that forecasts significant savings on the operational cost of up to 35% compared to the original proposal of an oil boiler. However, with an estimated renewable heat incentive of £1,562.16 per year based on the EPC certificate, this extends to a saving of 80.3% of comparative operating costs. In addition, there is also a massive reduction of 10,053 kg CO₂eq emissions per year, equivalent to an 89.8% decrease, compared with the initial intended oil boiler system.

Kevin Carling, managing director at Secon, said: "Our partnership with UK Alternative Energy means that we can deliver projects like this in the most efficient manner by combining our resources. Ultimately a new heating system needs to deliver what it is designed to do and be relatively easy to use. When a Panasonic TCap lends itself to a project, we know that we are using a system that provides the design heating capacity with no matter the temperature and can provide high leaving water temperature whilst maintaining its efficiency."

Derek Denton, managing director of UK Alternative Energy, said: “A lot of thought was needed to deliver a solution that met the customers' requirements - an easy-to-use system with full control integration, high efficiencies and a tight installation space for internal components. The amount of mechanical and electrical components installed in such a tight plant room space is a testament to the team that I work alongside. However, with careful planning, it shows what is achievable."

Highly Commended

Powerscourt Garden Pavilion (GS Renewable)

GS Renewable was recommended to Powerscourt Estate by CPG (The Cool Planet Group) because the client was looking for a company capable of making the estate the first zero carbon estate in the world in a major five-stage retrofit project.

The first stage was to provide space heating for the glass Garden Pavilion, eliminating oil completely and providing all heating requirements using heat pumps, with no fossil fuel back up. There was an existing UFH system in the pavilion which was heated by a 280kW oil boiler. The brief was to develop a control strategy which would integrate with the whole estate BMS. The existing boiler and ancillaries were inside the indoor plant section of the Pavilion, GS Renewable was asked to remove the system and build a portable plant rooms to be placed outside the glass house. This released valuable space back into the indoor plant section for additional stock.

After establishing the peak heating load requirements of 99.7kW for the pavilion, an air source solution was specified, using 2 x Viessmann Vitocal 300-A type AWO 302.B60 heat pumps with a combined output of 111.6kW / hr.

CHILLER PRODUCT

Sponsored by Climalife

Winner

Redefined YVAA (Johnson Controls – YORK)

The Redefined YVAA chiller from YORK is built to deliver flexibility, reliability and sustainability in both comfort and process applications.

- Flexibility: YVAA offers new combinations of performance to meet job requirements precisely.

- Reliability: YORK engineers design and manufacture critical components with decades of global experience, serving your project reliably with minimum planned maintenance, reducing ownership costs and downtime.

- Sustainability: Higher annual efficiency reduces Indirect Emissions over the service life of the equipment and reduces operating costs.

Launched in March 2022, energy efficiency is YVAA's main value proposition. It uses VSD technology with variable volume ratio (VI) screw compressors combined with EC fans that improve part-load efficiency and provide the highest SEER values in its range.

The highest part-load efficiency rations reduce the operating costs of the unit. The Redefined YVAA can be tailored and tuned to match the capacity, efficiency, sound and footprint of your specific application. Customization options and built-in features include optimized compressor options, compact footprint size and optimised sound.

The Redefined YVAA is designed to provide the best overall life-cycle costs through efficient performance, remarkable flexibility and optimised reliability. These design features, along with easy access to service components, provide a low cost of ownership. And with features and options that ensure an optimised chiller and years of worry-free operation, the Redefined YVAA provides greater reliability and real-world efficiency. In addition, YVAA can be connected to the platform OpenBlue Connected Chillers for remote access and monitoring.

Highly Commended

GoracChiller (G&O Refrigeration)

G&O Refrigeration’s offering in this category is suitable for multiple cooling applications, including ice rinks, cold stores and refrigeration.

The GoracChiller features variable speed compressors, lead/lag pumps and built-In gas detection. The variable speed compressors, along with the built-in PLC programme, allow the chillers to turn off when the target temperature has been achieved for a period of time. The programming and compressors have been set up to gradually ramp up and down, eliminating spikes in power.

In addition to energy efficiency, the units also offer heat recovery options for use in applications such as swimming pool heating, underfloor heating and pre-heat cold water supplies.

The units can fit through a set of standard double doors to ease installation, while the frame has pre-drilled holes for castors. The PLC programme is set up and ready to be used and control valves, strainers and cooling pumps are all included. Pumps are modulating.

COMPANY ENVIRONMENTAL INITIATIVE

Sponsored by MBS

Winner

ViMove (Viessmann)

Viessmann has underlined its commitment to climate conservation with a unique initiative which sees the company donates trees to offset CO₂ emissions as rewards for exercise completed by participants.

Viessmann’s partners already reduce CO₂ emissions by 500,000 tons per year just by replacing old boilers. With #ViMoveForClimate, the company is expanding its support for the cause.

The idea is simple: participants do the exercise, and Viessmann rewards their commitment by donating trees – every kilometre and every minute counts. To track sport activities and CO₂ offset, Viessmann has developed its own ViMove app. Participants can improve their health while making a contribution to climate conservation at the same time. To ensure that people can make the most of their exercise, there are almost 30 types of sports to choose from.

The company says the innovation combines the very simple and fun solution of tracking sports in a state-of-the-art app with the topic of sustainability. It believes this is the only way to engage as many people as it did in such a short period of time and to really start a movement.

Viessmann gave every staff member a Garmin watch to help track their activities and to add to the ViMove total. The company then plants trees to offset CO₂ emissions. In 2021, Viessmann reached the milestone of one million trees together with the global family of ViMove users. In this way, 10,000.04 CO₂ tons per year will be captured. A healthy tree lives, on average, 100 years and compensates approximately 1 ton CO₂.

Almost 8,000 people from more than 50 countries have joined the movement, resulting in 1.1 million km of exercise by employees. Fifty countries have taken part, supporting tree planting projects in the UK, Uganda, Kenya, Germany, Peru and Haiti.

Highly Commended

Compressor Replacements (GEA Heating & Refrigeration Technologies)

GEA Refrigeration (Leeds) and several other providers were given the opportunity to look at a service project to upgrade the controls and carry out the service exchange of seven compressors packages across five refrigeration plant rooms to increase reliability of a refrigeration plant.

When the client gave the go-ahead, GEA carried out the replacement of the compressor packages and replaced the controller with a new OMNI controller.

GEA also carried out the installation of Danfoss VSDs to the compressor drive motors, allowing for fine tuning of the operating conditions of the compressors and saving further energy.

Unique features of the project were the introduction of inverter control, OMNI controller, high efficiency motors and GEA’s latest compressor technology.

DOMESTIC GROUND SOURCE PROJECT

Sponsored by Cross Group

Winner

Lime House (GS Renewable)

GS Renewable was recommended by Viessmann for this project because the client was looking for an integrated system to provide heating, cooling, domestic hot water, mechanical ventilation and heat recovery. The water services were to be pressurised with an insulated potable CW tank, while the heating and cooling is through a UFH system with dew point controls. The client also wanted to generate electricity with a PV system from another building with available roof space on the site.

After establishing the heating and cooling load requirements of 10kW for the new build, it was decided to use a geothermal system with 2 x 110m vertical bore holes. MuoviTech 40mm Turbo probes were used to increase the efficiency of the collector by 33%.. A Viessmann Vitocal 200-G BWC 201.B10 was used to provide 500l DHW, heating - 500lt buffer tank at 35℃ and a 500l chilled water tank for cooling.

The system is designed for passive cooling but when the HP is in operation providing DHW during cooling requirements, chilled water from the HP goes to the chilled water tank before it goes through the bore holes to collect more energy. This means there is a reduced energy requirement during cooling until the chilled water is within the 2℃ of the dew point cooling requirement.

The following primary energy requirements are based on some estimations and some facts which could be calculated, due to the new building not being inhabited for one full year. HP electrical primary energy / hr = 1.69kW; average HP primary consumption / day spread over 365 days = 8.67kW; HP primary electrical energy consumption annually = 3.16MW; house electrical energy / day = 20.96; estimated daily electrical energy consumption = 30kWh; estimated annual electrical energy consumption = 10.95MW; estimated annual electricity production from the PV system = 20.352MW

There is a second house on the site with a swimming pool, which was included in the design process. The system is able to export 9.4MW / year from Lime House to the second property. Hence Lime House primary energy requirements from the grid will be zero, and Lime House will be an exporter of energy.

Highly Commended

Urban GSHP Installation in Family Home (R A Brown Heating Services)

The customer required a future-proof renewable heating system and wished to maximise energy efficiency with a ground source heat pump. Whilst he had a large garden, there was not enough suitable area for the ground collector and therefore boreholes were the only option available, with the old utility room used as the plant room.

The original total heat requirement meant that a 16kW NIBE unit was considered, but this required 3-phase electricity and pushed the project beyond budget. A recommendation was made to add heat insulation to a small section of the outside walls; this reduced the heat requirement to 44038 kWh/yr and meant a 15kW Steibel Eltron GSHP, able run on single phase electricity, could be specified. Three 150 metre boreholes were drilled, with 14 radiators upgraded along with the pipework.

The estimated annual CO₂ emissions for the existing gas boiler system was 9247.98 kg CO₂/kWh per year. The estimated annual emissions for the GSHP is 1338.37 kg CO₂/kWh per year, a saving of 7582.16 kg CO₂/kWh per year.

HEAT PUMP INSTALLER

Sponsored by Grant Engineering UK

Winner

R A Brown Heating Services

R A Brown Heating Services has been installing ground and air source heat pumps since 2007. In 2012 the company moved into showroom premises having previously been run from a home office and steadily grew from 7 employees to 21 today.

Richard Brown felt strongly that prospective customers need to see the different technologies and understand how the system will fit into their property. In the showroom they can see mechanical ventilation heat recovery (MVHR) systems, radiators, underfloor heating (UFH), wall heating, ground source heat pumps (GSHP) from NIBE & Stiebel Eltron, air source heat pumps (ASHP) from NIBE & Stiebel Eltron.

The installation team comprises of 8 fully qualified engineers and 4 apprentices. In addition, the company employs a technical designer providing design services for air and ground source heat pumps, heat recovery ventilation systems and solar thermal systems. He provides advice to new customers and produces technical drawings, including heating distribution, underfloor heating loop plans, hot and cold water and MVHR ventilation layouts as well as specification documentation to suit particular project requirements. He also assists in site surveys to enable accurate assessment and calculation of heat loads in accordance with the Microgeneration Certification Scheme (MCS), identifying the installation requirements and production of CAD plans.

In the last 14 years, R A Brown has completed 322 air source heat pump installations and 94 ground source heat pump installations in Norfolk and North Suffolk. Most of the retrofit installations undertaken have involved removing an oil system where the boiler has reached the end of its life. This is the opportunity which comes round once every 15 to 20 years to offer a renewable heating system. Over the years we have found that when offered a renewable heating option that this is the preferred option which has been chosen by customers.

Highly Commended

Calibrate Energy Engineering

The company has been built on to decades of heat pump and heating/chilling experience in various industries and locations. Shane and Susie McDonald founded Calibrate Energy Engineering in November 2012, having previously owned and operated a similar company in New Zealand which they founded in 2006 and sold in 2012 to relocate to the UK.

Based in rural Northumberland, the pair have built a dedicated team of experts targeting commercial, high-energy users, in the hospitality and agricultural sectors and are now expanding into plastics, waste management and other energy hungry industries. Calibrate is dedicated to offering a ‘hands off’ renewable system by using an integrated bespoke control solution to remotely monitor tariff generation and manage the operation of a ground source heat pump. This innovative technology is not commonplace in the UK to the extent of the true ‘hands off’ Calibrate solution, which enables clients to focus on running their already busy enterprises with minimal disruption.

HEAT PUMP PRODUCT

Sponsored by the Heat Pump Association

Winner

Aerona³ R32 Air Source Heat Pump Range (Grant Engineering UK)

While there is no single heat pump system suitable for all installations, it is the versatility of the Aerona³ range from Grant Engineering that impressed the judging panel. This versatility allows engineers to choose the installation method that is the best fit for their customer's requirements, be that using a low loss header, a buffer or even a plate heat exchanger. This flexibility with installation is quickly making the Aerona³ a popular choice with heat pump installers.

The Aerona³ R32 heat pumps are primarily designed for the domestic heating market, suiting new build and older properties, houses and flats. The range is also suitable for smaller commercial properties, such as offices, and comprises four models in outputs from 6kW up to 17kW , with a 7-year guarantee when installed through Grant’s G1 Scheme.

Recent projects include four Aerona³ 17kW units installed at Caerphilly Council Tir Y Berth Depot by Heatforce Cardiff. This commercial installation was recognised for its green credentials being awarded the Welsh Energy Efficiency Awards Winner in early 2022.

An exclusive development at Whittonditch Farm Barns in Ramsbury, Wiltshire, selected Aerona³ heat pumps for all four properties as well as installing Grant cylinders and underfloor heating. The final property was completed in 2021.

Benefits for customers centre on efficiency, with excellent SCOPs helping homeowners maximise energy output, plus quiet operation. The Aerona³ is also compliant with permitted development in the majority of scenarios.

For installers, the units are straightforward to install and are supplied with a range of components as standard, including factory-fitted HE circulating pump, flexi hoses, remote controller and more. They are compatible with S, Y & W-Plan heating control systems and can also be supplied pre-treated with Blygold anti-corrosion treatment to site.

Highly Commended

Ecodan Hydrodan (Mitsubishi Electric)

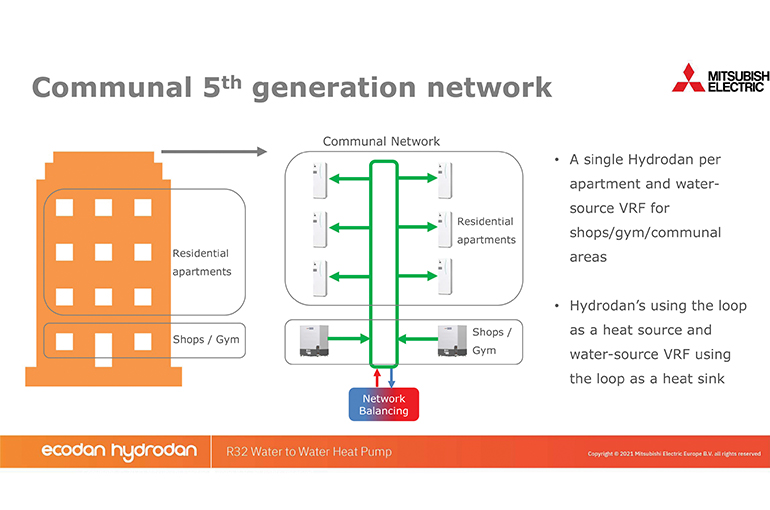

The Ecodan Hydrodan is a new, highly efficient, water-to-water heat pump for the multi-residential market. The packaged ‘plug & play’ solution is specifically designed to provide heating and hot water in residential apartments, and to capitalise on the significant sustainable energy efficiency that the next generation of heat networks (5th generation) offer. It also operates with a low quantity of low-GWP R32 refrigerant, to help keep environmental impact to a minimum.

There are already renewable heating solutions for single homes, but this is one of the first truly low-carbon options available for multi-residential apartments.

The Ecodan Hydrodan upgrades heat energy from the low-temperature water loop for use in each apartment. Each packaged unit offers a capacity range of between 1.1kW and 7.5kW with flow temperatures of up to 60°C. The 170-litre integrated tank includes variable PIC (Pressure Independent Control) Valve loop control, which allows the flow into the unit to change independently of the pressure in the system.

HEAT PUMP TRAINEE OF THE YEAR

Sponsored by Freedom

Winner

Stuart Perfect (GS Renewable)

GS Renewable managing director Thomas Vaughan says the only problem with Stuart Perfect is that they only have one of him!

Stuart has been with the business for less than a year, but has already worked on significant projects.

Thomas added: “I know everyone will think their nominee is the best, but in my 23 years in the industry I would describe Stuart as having made the highest level of progress in the shortest period of time. He will make a great contribution to the industry in the coming years when we are under pressure for engineers of this calibre to deliver Zero Carbon.’’

Stuart joined the business with experience of different engineering fields in conjunction with his studies for a mechanical engineering degree in Canada, and has since shown a great willingness to learn.

Thomas Vaughan continued: “He started like all our new engineers working with our fabrication team because we have a policy that everyone will get a better understanding of our systems and what we are trying to achieve by being involved in building our plant rooms.

Stuart has a great attitude and has progressed very quickly in his understanding of heat pump technologies; he absorbs new information at a highly impressive rate. He has progressed in one year from the basics to the very technical levels that I would normally expect to take three years.

Stuart was given the task of creating a commissioning document for a project in Jent but was not allowed access any other of our commissioning documents so that we could get a fresh perspective on how someone else would view and be able to commission. This is now the GS Renewable template document. We sent Stuart on his own to carry out commissioning, which he got more than 90% of the way without any assistance. The experience he gained for the last 10% was invaluable because there was a factory setting in the HP control which was causing an issue and the learning from this experience can only happen in practice.’’

Runner-up

Sam Groves (Finn Geotherm)

A positive attitude and exceptional standards of work earned Sam Groves a well-deserved nomination from Finn Geotherm.

Commercial director Gay Ransom said: “At Finn Geotherm, we believe we are well placed to provide training in heat pump installation skills. What we cannot teach, however. is attitude. Sam has this in spades. He has risen to every single challenge we have given him since joining Finn Geotherm in May last year.

“We are currently installing some of the largest heat pump systems in Europe and he has played a key role in these projects, not only in providing support for our qualified electrical engineers, but also now in installing the equipment on his own.

“At the age of just 21, Sam shows great maturity in his approach to each project and problem solving as required. He is without question a superb asset to our company and an example to his colleagues and others seeking to join the industry.’’

MARKETING INITIATIVE

Sponsored by Toshiba

Winner

With You on the Journey (Grant Engineering UK)

‘With you on the Journey’ from Grant UK is an ongoing customer support campaign. The future of the heating industry is set to change with landmark transformations which will greatly affect all those working in this sector and with this campaign, Grant UK wanted all their customers to be supported with the help they needed on the journey to a low carbon future. It was also pivotal that no customer felt unsupported as we work towards Net Zero.

Key milestones in the campaign include:

- Launch of the Grant eLearning Academy in July 2020. This comprehensive online customer training platform is available 24 hours 7 days a week, with a wealth of renewable product content, as well as modules on Net Zero and The Heat and Building Strategy.

- Production of 18 separate heat pump video tutorials and numerous blogs in March 2021. These resources were dedicated to helping educate customers on their heat pump systems.

- Introduction of new Technical Sales Engineers in the external sales team in May 2021. These additional roles were designed to provide onsite support to our customers when installing low carbon technologies.

- Expansion of G1+ rewards programme in March 2022 which saw Grant UK extend its support to renewable products through this loyalty scheme. The G1+ Points rewards tier allows installers to earn points on their boiler, heat pump and other renewable installations which they can then redeem for merchandise, home tech and electricals, and product training via the G1 Shop.

Uptake has been substantial, with over 4,000 user sign-ups since launch including installers, merchants, architects and specifiers. Grant has also partnered with merchant groups like Travis Perkins/City Plumbing and Wolseley to offer the training initiative to their branch colleagues nationwide.

Since the launch of the campaign in January 2020, Grant UK heat pump sales have grown by over 185%.

Highly Commended

Let’s START a Global Conversation! (OMEGA Solutions & Refrigeration Mentor)

Let’s START A Global Conversation is a dynamic collaboration between Refrigeration Mentor’s Trevor Matthews, who formerly led Emerson Canada’s training initiatives, and James Bailey of Omega Solutions, who previously founded and led WAVE Refrigeration.

The aim of the initiative is to market and promote our industry globally through offering free online training seminars/workshops.

On March 1, Trevor and James hosted a presentation and demonstration on the importance of sizing refrigeration services. The demonstration showcased the use of MicroPipe to size a typical retail convenience store that uses CO₂ as the refrigerant – where the suction, liquid, discharge and drain pipework was sized, and the importance of low line losses and pressure drops. Trevor then launched a 12-weekly event – CO₂ Mondays. He and James kicked of the first session to discuss the history, technical fundamentals and the operational characteristics of CO₂.

Both events attracted large worldwide participation and the aim is to expand the sessions to discuss the fundamentals and operational characteristics of A2L refrigerants.

NON-DOMESTIC GROUND SOURCE PROJECT

Sponsored by the Ground Source Heat Pump Association

Winner

West Ancroft 8,188kW Ground Source Heat Pump (Calibrate Energy)

Calibrate Energy has successfully installed one of the largest ground source heat pumps in the country (8.2 MW in total) for a farming client, WL Douglas, to increase grain drying capacity, productivity and profit and to drastically decarbonise. This project has been a showcase for Calibrate to demonstrate our mission to rethink and reshape how energy is more economically utilised and consumed.

The original 1MW installation took place in 2018 to speed up and streamline grain drying and the cooling process using Calibrate’s innovative heat/chill process. Fast forward three years and the client added 6.2MW of capacity incorporating 60km of below-ground pipe work.

The client has since upgraded the system again, adding a further 1MW capacity thanks to the capacity of the original ground loop, hence the 8MW total capability. This meant that when Ofgem started to offer modified capacity, Calibrate was able to quickly and efficiently grow this system without business disruption. This was based on Ofgem rules that existing systems could extend and receive payback for their remainder of the RHI tariff term for specific uses. This was the first ‘modified capacity’ for Calibrate and further ones are in the pipeline.

The key driver for the upgrades was thanks to the performance of the original system, and the rapid growth of the WL Douglas business, which has resulted in a grain and grass drying requirement of some 30,000 tonnes.

The new ground source heat pump heats and dehumidifies the air before it is passed through the grain and grass on the drying floor whilst the chilling by-product is used to dehumidify the air onto the drying system, chill the produce post drying and aids overall efficiency of the system. As well as, servicing the produce, this system also provides workshop heating, hot water for truck washing and is future proofed with additional plate exchangers to accommodate this expanding business.

Highly Commended

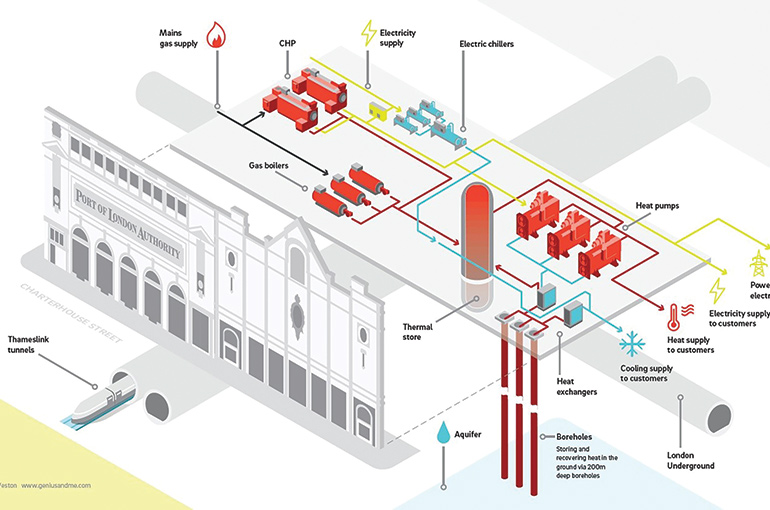

HFO Heat Pumps for E.ON Citigen City of London Energy Network (Carrier)

Carrier AquaForce 61XWHZE high-temperature heat pumps operating on ultra-low global warming potential HFO R-1234ze refrigerant were chosen for E.ON's ground-breaking district heating and cooling scheme in the City of London. The project is anticipated to cut carbon emissions from heating and cooling by customers connected to E.On’s City of London network by up to 50% and will enhance air quality in the city by reducing emissions.

Three heat pumps extract thermal energy from water pumped from deep boreholes in the aquifer 200 metres beneath the capital. They will also harness waste heat from the existing Combined Heat and Power plant that would otherwise be lost to atmosphere. The Carrier units upgrade the energy harvested to produce hot water at 80°C. This is used to provide up to 4MW of heating and 2.8MW of cooling to residential and business customers via a district-wide network of highly insulated pipes, running underground for 10 kilometres.

RACHP WOMAN OF THE YEAR

Sponsored by RACHPskills UK

Laura Bishop

Chair, Ground Source Heat Pump Association

Laura Bishop is a chartered mechanical engineer by profession and has over 21 years of experience in the industry, working for blue-chip companies such as Bombardier Transportation, Rolls-Royce Fuel Cell Systems, Babcock Intec, and E.ON Connecting Energies. Besides being a Chartered Mechanical Engineer with the IMechE, She has completed an MSc in Renewable Energy Systems Technology.

She is the founder and director of independent renewable energy engineering consultancy, Infinitas-Design, based in Derby but serving clients across the UK and Ireland.

She is a strong advocate for heat pumps and encourages councils and developers wherever she sees new developments throughout the UK. She believes that heat pumps should be deployed in place of traditional heating and cooling systems.

As a qualified CIBSE Heat Network Consultant, she has influenced the use of heat pumps for low and ultra-low heat networks at local and national levels.

Paul Leedham, from Matrix Energy Systems, said: “She has tirelessly worked to help deliver all of the schemes within the Ground Source Heat Pump Association and Heat Pump Federation, while transforming both into trade bodies of the future.”

REFRIGERATION PROJECT / INNOVATION

Sponsored by Heat Pumps Today

Winner

Project Aquarius (SURE Solutions)

Cranswick Country Foods was assessing options for a new complex factory demand and engaged SURE Solutions for technical assistance during the feasibility stage. The heating and cooling requirements were dynamic, due to the highly versatile operational load profile that was essential in maintaining the finest product quality leaving the factory. There were three production lines and each would change to accommodate several product processes, all having varying refrigeration loads and operation temperatures. Once the project was approved and site works commenced it was constructed at a fast pace to ensure that the factory was in full production by February 2022.

The refrigeration system provided both heating and cooling peak loads in excess of 3MW covering varying system operational temperatures from -43°C up to +125°C. The operational temperatures and capacity of the plant could alter at short notice and when required it was to adjust smoothly and efficiently. Many trials were needed to ensure air temperature and air velocity were optimum across the system. This was paramount when product need to be processed, treated and sent for dispatch in minimum time. The refrigerant selected was ammonia, after considering CO₂, and this was used for the main system and as primary driver for spiral chilling, spiral freezing, air cooler evaporators, heat exchangers for secondary cooling and heat recovery processes. Additional to this, a cascade heat pump was incorporated into the design to provide the site with all hot water covering a large demand schedule, and was designed to maximise heat recovery when the refrigeration demand was high and storing water ready for peak hot water usage demands.

A comprehensive SCADA system was commissioned to control the plant to its optimum efficiency. All energy usage is monitored and commissioning was used to demonstrate the effectiveness in recorded data and making controlled changes improves the overall systems efficiency.

Highly Commended

Royal Berkshire Hospital Chiller Upgrade (Mitsubishi Electric)

When Reading’s Royal Berkshire Hospital needed to replace two aging chillers for its maternity block, a like-for-like replacement was going to take months to manufacture and transport. The introduction of three e-Series chillers meant the replacement work could begin immediately, and this started a process to upgrade and replace all the chillers throughout the hospital’s four main blocks.

Once the Royal Berkshire NHS Foundation Trust Board saw the improvements in efficiency and control that was available with the e-Series chillers, they took the decision to invest in the new equipment. Mitsubishi Electric’s own engineers then started the process of removing the old equipment and installing three modular e-series 180kW chillers. These are available ‘off-the-shelf’ and the modular design means up to six individual units can be connected together to provide a system capacity from 90kW to 1,080kW.

All of the units are also supported with centralised controllers and Mitsubishi Electric Variable Speed Drives (VSD), which help to reduce energy consumption and deliver large energy and running cost savings for the Trust.

TRAINING PROVIDER

Sponsored by Midea

Winner

Climalife – College Speaker Programme

Climalife prides itself on its technical expertise and as part of its efforts to share its knowledge and support with the cooling industry as a whole, it wanted to extend this support further within the education sector. So in May of 2021, marketing manager Mel Summers undertook a research survey with 45 participants, consisting of students, apprentices and tutors, to discover their thoughts on how established companies within the industry could best support them and their future careers. The response was excellent and the enthusiasm and yearning for knowledge was incredible.

Climalife shared the feedback from this research with the market with a view to raising awareness of the call for more support and then went on to launch its College Speaker Programme.

The sessions have evolved as each one has taken place and the team have found the more interactive aspects of the session has really opened up the discussions and debates with the learners. Topics such as refrigerant safety, legislation, considerations and selection processes have been covered and each of the colleges has requested follow up sessions. This has been a great opportunity to enhance the awareness of environmental considerations, such as choosing the right low GWP refrigerant as well as energy efficiency considerations.

Climalife is committed to driving the F-Gas phase down curve towards lower and lower GWP refrigerant usage. Content has also been flexible enough to cover topics that are on the current college agendas and so complemented one another. Climalife and Chemours collaboratively worked together to create training materials for the colleges.

This activity has worked hand in hand with support for the WorldSkills initiative, whereby Climalife has been able to support some of the competition activity with some refrigerant gas. WorldSkills gives our engineers the opportunity to showcase its expertise at a worldwide level, after having competed at various localised heats.

Highly Commended

Mitsubishi Electric – Blended Learning Programme

Mitsubishi Electric completely revamped its engineer training during the COVID pandemic and now, with an online learning platform, trains double the number of heat pump and air conditioning installers, saving both customers and the company money, while also reducing carbon emissions and waste.

The pandemic called for a complete rethink as all customer visits were halted and the response from Mitsubishi Electric’s training team was to develop an online, blended learning programme that enabled customers to train at a time to suit them.

Previously the company was teaching up to 8 engineers at a time but now, the blended learning can be given to up to 100 people at a time with a virtual programme that is delivered as interactive webinars. The training has been exceptionally well received by customers with 99% of attendees saying they would recommend the training to colleagues.

Mitsubishi Electric is now expanding the reach and opportunities for training even further, with an increase in the number of online courses and the launch of new hands-on training.

WHOLESALER / DISTRIBUTOR

Sponsored by Hitachi

Winner

Secon Renewables & AUK

Following the merging of AUK Distribution and Secon Renewables, and building on the back of their strong performance in 2021, both businesses continue to develop and improve the offer to their customer base. An increased product offering, large stock undertaking and improved technical support across both businesses have helped customers to operate as seamlessly as possible through a very difficult trading period. Material shortages, long lead times, price increase and logistics issues have created difficulties for most business over the past 12 months but investment in product, people and processes have enabled AUK Distribution and Secon Renewables to provide the high level of service expected of us by their customers.

The purchasing of products and management of prices has been the greatest challenge of the last 12 months. While most businesses have been managing cash flow and running on ‘just in time’ processes, AUK and Secon have bucked the trend and increased their stock holdings. Added to this, they have also gone out to the market and sourced alternative products to supplement their existing range, to ensure that product shortages have as little impact as possible.

The business is built around a slick, trade-only webstore and a single distribution warehouse which services national sales, providing next-day delivery to customers. In addition, to improve services to local customers AUK and Secon now have their own delivery vehicle, which means they are able to service customers in the North-east area with more timely deliveries. This benefits the customer as there is less lost time on site waiting for the delivery to arrive and removes the risk of damage as it passes through the distribution network.

The sister companies are moving to larger premises, increasing floor area by three-fold, giving them the capacity to carry more products in stock and allowing expansion into other areas of the market to continue the ‘one-stop-shop’ ethos.

Highly Commended

Freedom Heat Pumps UK

Freedom is one of the leading UK distributors of air and ground source heat pump equipment and accessories from all leading manufacturers, including Midea, Samsung, Hitachi, Red and Claussius. It operates from a trade-only northern warehouse based in Bamber Bridge, Lancashire, a southern branch in Southampton and a training base in Chorley, Lancashire.

The Freedom team is highly qualified and have a wealth of industry experience, skills and knowledge. Freedom sees itself as more than simply distributors of its products and aims to provide the best after-sales service and technical support throughout the installation journey.

Established in 2010, Freedom achieved turnover of &8.3 million in 2021, with a team of 27, and is aiming for £12m in 2022, having moved to a new 15000 sq ft warehouse, bringing stock and distribution in-house, increasing the technical resource, recruiting an in-house marketing team and establishing an MCS support unit.