04 August 2025

|

Danish manufacturer Solid Energy has upgraded its hydrocarbon range of high temperature modular heat pumps for the UK market, with the new line-up capable of reaching flow temperatures of 170C.

At a launch event hosted by the Danish Embassy in London, the large heat pump specialist highlighted the benefits of a solution aimed at customers looking to decarbonise process heat operations.

Industrial process heat applications in factories, food processing and distilleries are expected to be the main focus for the very high temperature applications, while the system can also provide cooling if required.

Operating on a choice of four hydrocarbon refrigerants, depending on application, the high temperature (HT) units use the same compressor technology and other components found in Solid Energy heat pumps already delivering low temperature district heating projects.

The refrigerant options are:

- Propane: for refrigeration and heat pump operation for heating purposes. Suitable for cooling between -30°C and 25°C, and heat output from 30°C to 65°C.

- Isobutane: for heat recovery and heat pump operation for district heating and industrial process heating. Suitable for cooling between -10°C to 40°C, and with heat rejection in the range 50°C to 95°C.

- Butane: for heat recovery and heat pump operation for industrial process heating and hot water. Suitable for cooling between 0°C to 50°C, and with heat output from 70°C to 120°C.

- Isopentane: for heat recovery and heat pump operation for industrial process steam and hot water. Suitable for cooling between 35°C to 90°C, and with heat output from 90°C to 170°C.

The system modules range in size from 200kW to 1.2MW, and multiple modules can be linked to give larger capacities controlled as one system. The semi-hermetic screw compressors boast a design life of 100,000 hours, requiring minimal maintenance and no oil changes, and are housed in noise-reducing cabinets for ultra-quiet operation.

Designed and built in Denmark, the heat pumps are delivered fully factory tested with minimal installation required, while integrated refrigerant leak detection and ATEX compliant ventilation ensures compliance with UK and European safety directives.

Ken Kneale, Business Unit Director UK & Ireland, said: “Every Solid Energy heat pump is designed to the specific needs of individual projects. Using our advanced performance calculator, we can select the appropriate compressor size. Depending on the operating temperature we then select the hydrocarbon refrigerants to be used.

“Our design flexibility allows us to implement multiple compressors using the same refrigerant or to select a combination of different refrigerants. This ensures that we can achieve the desired flow temperature while maximising the coefficient of performance (COP).’’

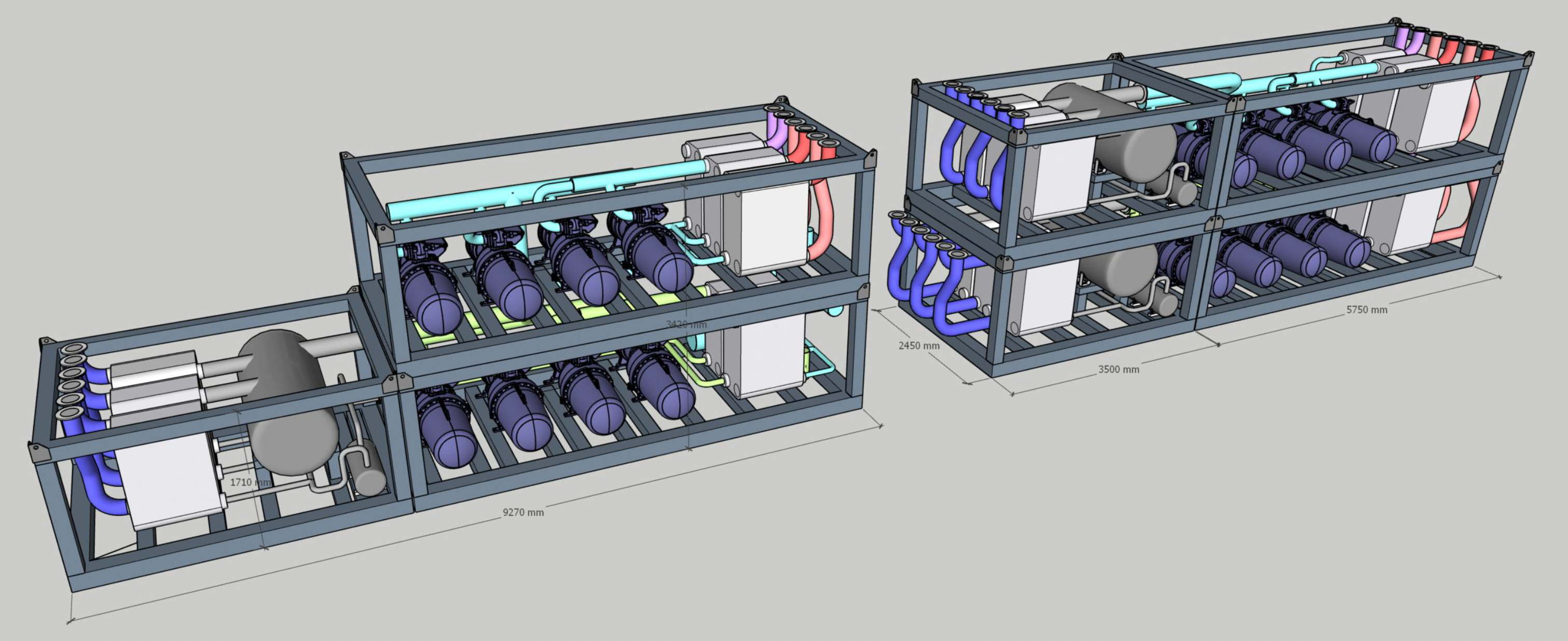

Also introduced at the embassy event was a totally new configuration of the technology, the XL4, aimed at projects requiring high output from limited floor space. Each XL4 module has four compressors, and Solid Energy is currently working to deliver a 70MW project in Denmark.

Kneale added: “The XL4 offers the same high efficiencies as our one cabinet, one compressor modular units with the benefits of needing less space and greatly reduced installation costs”

Solid Energy is working with specialist partner Pure Renewables Commercial in the UK, with the Hull-based business offering technical sales, installation, commissioning and aftersales support

For further information, please contact: Ken Kneale at [email protected] or visit www.solidenergy.dk

Solid Energy's XL4 modular heat pump with reduced footprint and capable of producing 170C flow temperatures