26 October 2023

|

Geoff Barker, Executive Director of Organic Heat Exchangers (O-Hx), says cold thermal energy storage systems can score highly for both flexibility and sustainability.

Ongoing efforts to decarbonise the cooling industry mean equipment manufacturers continue to seek ways to improve the efficiency of existing systems and develop new technologies. Any advances, however, are affected by the sustainability of the energy that powers them.

Most modern cooling uses electricity in some form and energy providers are working towards providing a more sustainable supply. But renewable levels are not yet sufficient to meet demand and this presents a considerable challenge.

Carbon intensity is a key indicator of how clean our electricity is, measuring how many grams of carbon dioxide (CO₂) are released to produce a kilowatt hour (kWh) of electricity. Electricity generated using fossil fuels is carbon intensive because the process by which it is produced creates CO₂ emissions. Renewable energy sources have a much smaller carbon intensity value (often zero) because they produce very few emissions.

This means that using electricity with a low carbon intensity value will reduce carbon emissions overall – particularly if used during periods when most clean electricity is being generated. The ability to take advantage of such periods of low carbon intensity on the grid results in reduced impact on the environment, as well as potential for lower costs.

The patented EnergiVault from Organic Heat Exchangers (O-Hx) is a cold thermal energy storage (CTES) solution which utilises artificial-led intelligence to access the electricity supply at low tariffs and at periods of low carbon intensity.

How it works

The system consists of a charger and thermal store, or battery, which is an insulated container, available in 1MWh capacity modular units. The system can be used alongside an existing chilled water system, on its own, or in place of an additional chiller. As with a chiller added to meet increased peak cooling loads, it can reduce the risk of production or building shutdowns, while additional features such as time of use (ToU) shifting, chiller optimisation, heat recovery and energy monitoring can be applied across a site’s entire cooling plant.

The system’s ice crystalliser charges the battery by converting the heat transfer fluid (HTF), typically a water/glycol mix, into spherical ice crystals a fraction of a millimetre in diameter, each surrounded by a film of organic material. This ice slurry acts as the phase change material (PCM), delivering a huge increase in the surface area over which the thermal transfer takes place.

The energy exchange rate of a single block of ice would be lower than found with multiple crystals of ice, or an ice slurry when stored inside the thermal vault the ice slurry takes the shape of a perfectly spherical crystal to avoid the clumping typically found in dendritic shards and increases surface area to volume ratio further. The spheres are surrounded by a parent fluid specially formulated with a freezing point below the ice sphere it supports, inhibiting fusion while in storage.

Most phase change batteries have the limitation of a low discharge rate because of the surface area to volume ratio, and cannot always meet a required load. By maintaining an ice slurry as its thermal store, EnergiVault significantly increases the range of energy transfer at any given time.

As an alternative to storing energy in electrochemical batteries, such as the lithium-ion examples in everyday use, thermal energy batteries do not reduce in capacity over time and therefore avoid the resulting loss in energy capacity experienced by lithium-ion storage.

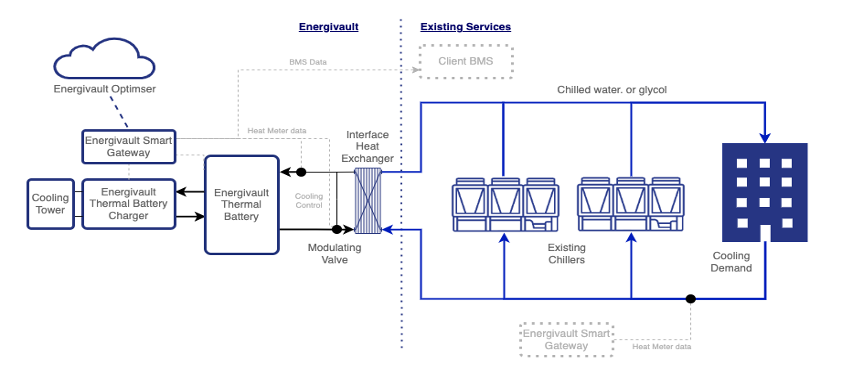

A schematic of EnergiVault illustrating its components, AI optimisation and integration with an existing building's chiller system

System integration

Using the example of an ongoing test site at drug development and manufacturing accelerator Quotient Sciences in Alnwick, the installed system is connected to the customer’s chilled water circuit, delivering cooling using two chillers. The system is interfaced with EnergiVault via a heat exchanger, which decouples the working fluid of the EnergiVault from the working fluid of the customer system, allowing EnergiVault to customise its storage temperature for optimum performance.

A blending valve allows integration into any existing chilled water system, providing flexibility on rate of discharge from the battery. The valve either supports the current chiller operation by adding a controllable amount of additional cooling or is positioned to provide 100% cooling capabilities.

As well as providing crucial system back-up for breakdowns or planned maintenance work, EnergiVault has also demonstrated its value in a number of varied operational situations.

Full load displacement by EnergiVault to negate peak tariff energy cost or electricity supply either high carbon intensive generation

Meeting Full Demand

Where a chilled water system is designed for maximum efficiency at full load, existing equipment may operate inefficiently in part-load conditions. EnergiVault is able to displace this inefficient operation by serving the building load with efficiently stored thermal energy, due to its discharge flexibility. In the second variant, EnergiVault delivers the full load for a defined period, usually triggered by high electricity tariff or high distribution charge periods. In this instance, the existing chiller switches off and is replaced entirely by EnergiVault.

Energivault supplementing a sustained load in excess of the existing chiller capabilities

Supplementing Sustained Peak Demand

A building’s cooling demand can often increase over time as a business develops and grows, leaving the existing system unable to meet peak load, usually resulting in building or manufacturing shutdown. In this scenario, EnergiVault would deliver all the peak demand above chiller capacity. Similarly, it can manage the stresses on cooling systems caused by unprecedented summer temperatures.

EnergiVault bridging peak loads when it would be inefficient to operate a second chiller at low loads to meet demand

Meeting Intermittent Peak Demand

Where the excess cooling demand has fluctuating peaks throughout the day, a traditional solution would be to introduce a second chiller, cycling and on part-load, which again can impact operating efficiency. EnergiVault is able to meet the fluctuating demand points through its efficient thermal storage and variable discharge rates.

An additional example of how the system can be used is for back-up energy storage, where a proportion of EnergiVault’s capacity is always held back in case of chiller related or other supply problems.

Heat Recovery

Further efficiencies can be achieved by the recovery of waste heat to generate hot water, space heating and other process heat requirements. Both high (100°C) and low (40°C) grade heat generation is possible with multiple storage options.

Summary

EnergiVault is not the only CTES solution available but the innovative use of ice slurry as the phase change material means it stands alone in terms of energy discharge flexibility and load matching capability. Used in place of an additional chiller, it can provide extra cooling capacity and highly efficient support in part-load conditions. Factor in the benefits of artificial-led intelligence to reduce carbon intensity and increase operational efficiency, and the proposition becomes stronger still.

For more information visit https://www.o-hx.com/