22 June 2022

|

ADVERTORIAL

Refrigerant leaks are a little like Government leaks; they go with the territory. But while the Government variety is unlikely to harm the environment, leaking refrigerant, if left unchecked, definitely can.

Yes, they’re a lot safer now in some respects, but as long as flammable and toxic gases are in use, we have to be vigilant. Currently 4,000 tonnes of gas are sold annually, of which 400 tonnes are lost through leaks in air conditioning and refrigeration units.

And if that refrigerant leaks, it can also lead to slips and trips, the most common cause of major injury in the UK retail sector. According to the HSE (June 2021), a single incident can cost a company £15,000 or more, and that’s not counting the cost of repairing the resulting reputational damage.

It’s just as well we’re blessed with engineers who know how to track leaks down, keep units operating efficiently and save customers from possible prosecution due to non-compliance. We call them the detectorists because they’re the ACR industry’s super sleuths, but they have a challenging time ahead.

Supporting engineers to do their job

As the planet heats up, so do sales of AC and refrigeration units. The International Energy Agency (IEA) estimates that global demand for space cooling alone will more than triple by 2050, so we need to give engineers the tools that will not only help them do their job effectively, but to be able to do it quickly and with ease. At Aspen we have a range of Advanced chemicals and Javac tools that help to take the guesswork out of detection, from our bubble-ups, dye and injection kits to our electronic leak detectors. We know that one size doesn’t fit all, which is why our range is large and improving all the time. Here’s a round-up of our top detectors:

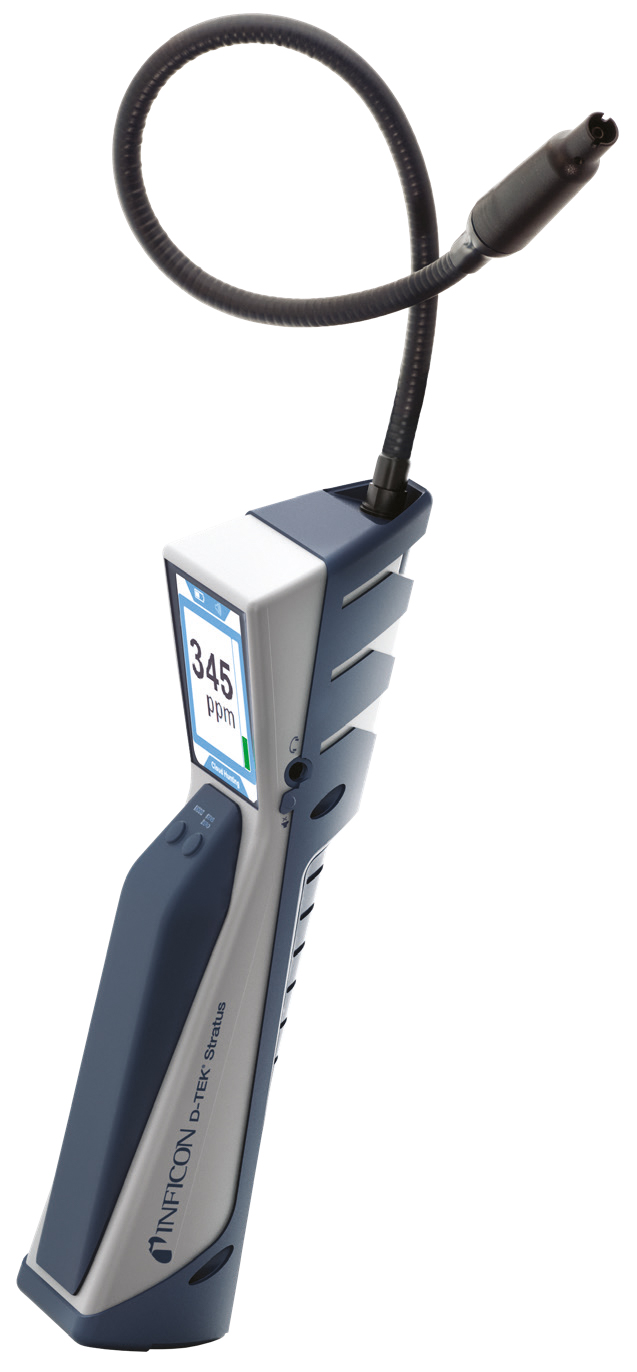

The Inficon D-Tek Stratus

Leak sprays: RTU BU (1L) and Easy Find (400ml) from Advanced are specifically designed to locate refrigerant leaks. Standard leak spray detectors are designed for use with natural gas, these are unsuitable as their lower viscosity means they will not cling to surfaces as effectively and can be blown off the pipework before the refrigerant leak is identified. Our leak sprays are economically quick and conveniently suitable for leaks across many applications.

Fluorescent dye and injection kits and cartridges: Our Spectroline range of dyes and sealers are simple to use, give an immediate visual result and once in the system, provide an excellent preventative maintenance tool. They can detect leaks from meters away, are perfect to use in awkward spaces and near moving parts and they’re fully compatible with all popular refrigerants and oils. Too good to be true? Well, in the wrong hands, they can be messy!

Electronic leak detection: We have a comprehensive range of electronic detectors including the UK’s best-selling TEK-Mate and the D-TEK Select next generation - D-TEK 3, which are both A2L compatible. But if you’re looking for the best of the best, then you need to check out the game-changing D-TEK-Stratus, which is tailor-made for the retail sector. This is the world’s first hand-held cloud-hunting leak detector with an LCD readout. There are three operating modes - cloud hunt, pinpoint and manual - to locate leaks faster than ever and has an infrared sensor that has the longest life on the market. And it detects all CFCs, HCFCs, HFCs, HFOs and A2L gases.

https://www.aspenpumps.com/en-gb

Tools Talk is sponsored by Aspen Pumps Group