27 May 2016

|

Barry Lea

Barry Lea Supermarkets are intensive consumers of electricity – yet few are taking advantage of modern techniques for achieving dramatic savings. Barry Lea, Chairman of Advanced Engineering, explains all.

(Edited: 6 June 2016)

Electricity consumption by supermarkets in the US and France is estimated to account for 4% of the country’s total annual electricity use.

On a national scale that’s a staggering amount of electricity, with supermarket managers under constant pressure to reduce their store’s energy demands and operational costs.

One key to achieving this has emerged via a landmark study conducted by US experts ASHRAE (the American Society of Heating, Refrigeration and Air-Conditioning Engineers).

(Edited: 6 June 2016)

Electricity consumption by supermarkets in the US and France is estimated to account for 4% of the country’s total annual electricity use.

On a national scale that’s a staggering amount of electricity, with supermarket managers under constant pressure to reduce their store’s energy demands and operational costs.

One key to achieving this has emerged via a landmark study conducted by US experts ASHRAE (the American Society of Heating, Refrigeration and Air-Conditioning Engineers).

The study provides concrete empirical evidence – for the very first time – that substantial reductions in energy consumption and significant cuts to electricity bills can be achieved simply by cleaning a HVACR system.

Modern cleaning methods are key

At Advanced Engineering, we have long argued that large HVACR efficiency savings can be made by adopting effective, regular maintenance regimes.

Achieving those gains, though, depends on using modern cleaning chemicals specifically formulated to thoroughly deep clean a HVACR system.

Achieving those gains, though, depends on using modern cleaning chemicals specifically formulated to thoroughly deep clean a HVACR system.

As an example, one of the new generation of smart, heavy duty cleaners – SuperClean – uses a powerful chemical foaming action to make light work of removing even the most stubborn scum and baked-on dirt, as well as inhibiting future oxidation.

The heavy duty SuperClean and its sister product EnviroCoil – formulated for more regular maintenance routines – are both designed to clean outdoor condensers, but the indoor shop floor cabinets also need to be regularly cleaned to significantly reduce their running costs.

The heavy duty SuperClean and its sister product EnviroCoil – formulated for more regular maintenance routines – are both designed to clean outdoor condensers, but the indoor shop floor cabinets also need to be regularly cleaned to significantly reduce their running costs.

CoolSafe is one of the new generation of environmentally friendly cleaners that is approved by the NSF (National Sanitation Foundation) for use in food preparation areas, making it ideally suited to clean evaporators in shop floor cabinets and refrigeration units.

Note that it is only by deep cleaning to the metal – removing the baked-on dirt, grime and bacteria build-ups that clog, cling to and slow both evaporators and condensers – that these system’s running costs can be reduced so drastically.

Note that it is only by deep cleaning to the metal – removing the baked-on dirt, grime and bacteria build-ups that clog, cling to and slow both evaporators and condensers – that these system’s running costs can be reduced so drastically.

For supermarkets, therefore, the solution begins with choosing the appropriate modern cleaning methods and products; it continues by looking in detail at the constituent parts of an average store’s energy bill.

Content continues after advertisements

Supermarkets: breaking down the problem

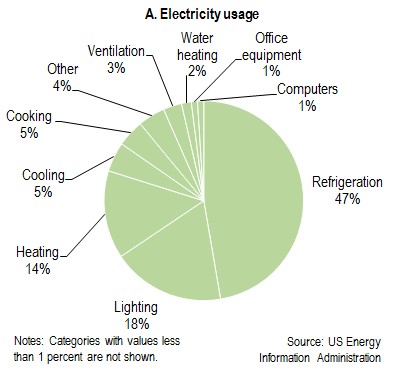

| When we separate out the individual components of a typical supermarket’s energy bill, it’s clear that one single element stands head and shoulders above the others. As we can see from the above breakdown by the US Energy Information Administration, refrigeration (the chillers, cabinets and freezer units, both instore and in stockrooms) accounts for the largest slice in the supermarket energy usage pie by a country mile: typically 45-55% of the total electricity used. It’s clear, therefore, that any attempt to reduce electricity costs by supermarket and facilities managers must begin by tackling the energy demands made by refrigeration systems. |

Introducing the solution

To see how this works we must look at the hard facts of the ASHRAE study. In the analysis, the owners of a building at 1500 Broadway on Times Square in New York City wanted to know exactly what impact HVAC cleaning had on the energy efficiency of their air con systems.

To do so they measured energy demand from the system for a week *before* cleaning and then again for a week after cleaning (concurring with ASHRAE Guideline 14-2002 on how to accurately measure HVAC energy savings).

To ensure the study was reliable and independent, the building owners hired a certified and independent testing, adjusting and balancing (TAB) company to test and calibrate their data collection methods and instrumentation during the trial.

To do so they measured energy demand from the system for a week *before* cleaning and then again for a week after cleaning (concurring with ASHRAE Guideline 14-2002 on how to accurately measure HVAC energy savings).

To ensure the study was reliable and independent, the building owners hired a certified and independent testing, adjusting and balancing (TAB) company to test and calibrate their data collection methods and instrumentation during the trial.

The ASHRAE study

| The 34-storey building in NYC has 1.2 million square foot of floor space which has to be cooled from 6am to 6pm using four large 30-year-old air handlers:

After testing during the first control week, SF-8 and SF-9 were taken offline for two days to perform a modern deep clean on both air conditioners. The two systems were then put back into service and tested in exactly the same manner for a further week afterwards. | In all, HVAC inspectors and TAB contractors continuously measured 54 different data points from the two air con systems for a week before and a week after cleaning, including:

|

Results

The ASHRAE study found that cleaning each system decreased coil differential pressures by 14%, which produced a corresponding increase in the flow rate and overall cooling capacity of the system by the same amount.

After cleaning, the smallest air conditioning unit of the four – SF-9 – started punching well above its weight, adding an extra 19-22 tons of cooling capacity (an additional 67-77 kW), increasing its overall capacity by a massive 25%.

The thermal efficiency of the cooling coils in the cleaned systems increased by 25%, and condensate water temperature dropped from 3-4°C before cleaning to 1-3°C after.

The inspectors estimated that 100 tons (352 kW) of cooling capacity would be added to the building once all four air handlers had been cleaned and restored in this manner.

After cleaning, the smallest air conditioning unit of the four – SF-9 – started punching well above its weight, adding an extra 19-22 tons of cooling capacity (an additional 67-77 kW), increasing its overall capacity by a massive 25%.

The thermal efficiency of the cooling coils in the cleaned systems increased by 25%, and condensate water temperature dropped from 3-4°C before cleaning to 1-3°C after.

The inspectors estimated that 100 tons (352 kW) of cooling capacity would be added to the building once all four air handlers had been cleaned and restored in this manner.

Conclusion

Evaporator coils before and after in one short close-up

Evaporator coils before and after in one short close-up Based on year-on-year HVAC building costs, ASHRAE estimated that cleaning one of the air handlers resulted in efficiency improvements that will lead to energy savings of up to $40,000 each year.

These kinds of savings make dramatic reading, and it’s important to point out that if these regular services also included cleaning evaporators in supermarket cabinets, costs for a supermarket’s annual energy bill would be slashed even further.

This is clear statistical evidence that very significant efficiency gains and substantial reductions in energy consumption can be made simply by cleaning and maintaining the air conditioning condenser on a routine basis.

More than ever, supermarket managers and operational staff must appreciate the importance of paying more attention to the state, cleanliness and efficiency of their store’s ACR systems.

These kinds of savings make dramatic reading, and it’s important to point out that if these regular services also included cleaning evaporators in supermarket cabinets, costs for a supermarket’s annual energy bill would be slashed even further.

This is clear statistical evidence that very significant efficiency gains and substantial reductions in energy consumption can be made simply by cleaning and maintaining the air conditioning condenser on a routine basis.

More than ever, supermarket managers and operational staff must appreciate the importance of paying more attention to the state, cleanliness and efficiency of their store’s ACR systems.

Your local wholesaler can advise you on the products you need but if you’d like information on the best regime for your premises you can explore our website www.advancedengineering.co.uk or speak to an advisor on +44 (0) 1256 460 300.