11 November 2021

|

Starfrost has installed a spiral freezer system for premium pet food manufacturer Butternut Box as the firm expands production of its freshly prepared dog food.

A move into a recently-acquired industrial unit measuring over 150,000 sq ft has enabled Butternut Box to invest in the latest technology and, when it came to expanding production capacity and upgrading its entire static freezing system, Starfrost was selected to provide a turnkey cooling solution.

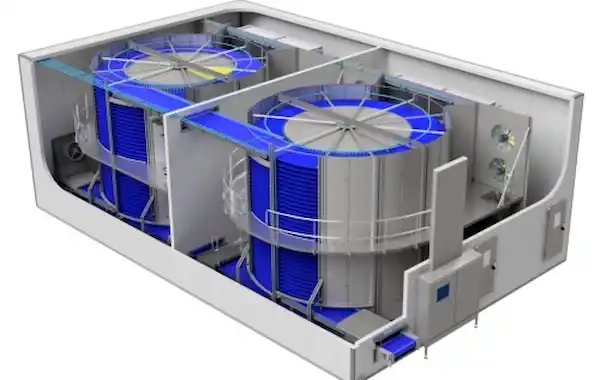

Working in partnership with parent company Star Refrigeration, Starfrost implemented an end-to-end cooling solution that has delivered benefits of energy efficiency and improved product quality. Starfrost designed, manufactured and installed a Double Helix spiral freezer that operates using an ammonia refrigeration plant supplied by Star Refrigeration.

The Double Helix spiral freezer has been designed to freeze approximately 4000kg per hour of vacuum packed dog food pouches, which has helped Butternut Box to double its processing capacity. The automated spiral freezer provides a continuous freezing solution that has delivered significantly reduce freezing times, improving the quality of the freshly prepared products.

Marco Attanasio, head of strategic projects, said: "Butternut Box has recently made a large investment to implement new technology within our processing line to drive continuous growth of the business. Our new spiral freezer and refrigeration plant forms part of that strategy and has assisted the business with doubling production this year. The design specification also supports our overall growth plans allowing for future expansion.

"Since the installation of our new freezing equipment, we have considerably reduced our freezing times in comparison to the static freezers that were used before and the method of freezing is consistent which has greatly improved the quality of our end product."

Starfrost worked with the customer to design a freezing solution with high efficiency and low carbon footprint in mind. The Double Helix spiral freezer operates with two separate temperature zones which significantly reduces the total number of kWs of low temperature refrigeration required to freeze the produce. This reduces the overall operational cost of the refrigeration system and emits less carbon into the atmosphere, whilst improving quality of the packaged products.