08 December 2020

|

A-Gas Managing Director John Ormerod explains how the cooling industry can continue to handle the Covid-19 pandemic, the F-Gas step downs and the effects of Brexit in the months ahead.

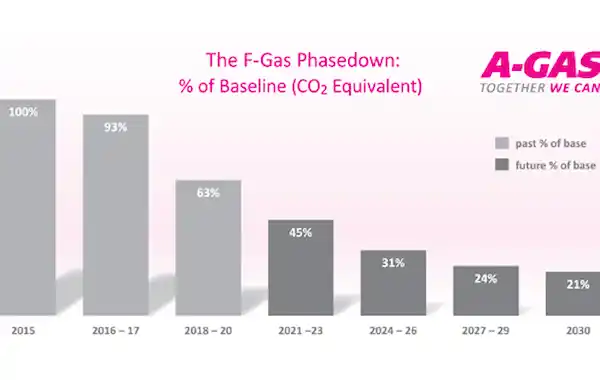

Looking ahead to 2021 it will be another year of great change for the cooling industry. Already planned is a cut in the F-Gas quota of 29% for virgin HFC refrigerants. On the face of it this alone would be a significant challenge for our industry in normal times. But when you also factor in our departure from the European Union and the demands forced upon us by the Covid-19 pandemic, there’s more than enough issues for our industry to cope with next year.

F-Gas phase down

The ban introduced in 2020 on the use of HFCs with a GWP of more than 2500 in new systems – except below -50°C in stationary systems – is something our industry has adapted well to. The ban on servicing existing equipment with virgin HFCs with a GWP of more than 2500, where the charge is greater than 40 tonnes of CO2, is also something we are well equipped to handle.

Next year’s reduction of 29% (on a CO2 equivalent basis) in virgin quota will take the industry down to 45 per cent of the 2015 baseline level. This will without doubt lead to a significant reduction in the supply of HFC refrigerants. The F-Gas step downs have at times led to price rises and shortages and it is likely we’ll see these again next year. On the whole the industry is learning to cope with the long-term effects of these changes and this is evident in the sales of low GWP replacements.

Refrigerant recovery and reclamation have a big role to play as we look at ways to meet the continued challenges offered by the F-Gas step downs. Industry experts know that refrigerants saved from disposal and returned to use as reclaimed gas can make a direct contribution to the reduction in use of virgin refrigerants and help the industry remain within the limits imposed by the quota system.

Reclaimed refrigerant sent to A-Gas reprocessing centres undergoes chemical analysis, is cleaned of contaminants and goes through our separation plant to produce a product that matches that of virgin refrigerant requirements.

Using reclaimed refrigerant is a direct way of lowering the carbon footprint of your customers. You will be saving on the use of raw materials, energy consumption and unnecessary transport normally associated with virgin production. In today’s modern society, end users and customers are beginning to demand that their goods and services are produced and delivered in less wasteful ways.

Using reclaimed material is part of the cooling industry’s sustainable future. Our industry is well placed to reap the benefits of this circular economy – the opposite to the use and discard business model. Through the recovery and reclamation of refrigerants we are putting in place the building blocks to adopt a more holistic approach to the way that we carry out our business. New refrigerants are emerging all the time and I have no doubt that we will develop more efficient ways to increase their longevity.

My advice to end users is to have retrofit programmes on their 2021 agendas – if they haven’t done so already. Help is on hand from your refrigerant suppliers to ensure that you and your maintenance team have all that’s needed to make the switch to low GWP gases or take the reclaim option. Both will help soften the blow of the F-Gas step downs.

Brexit

The UK has already left the European Union but the effects will only be felt after the end of the transition period which ends on December 31 this year. The industry is hoping for a smooth transition with low barriers to trade and the UK continuing with the like-for-like standards and regulations it shares with its continental counterparts.

The F-Gas Regulation is UK law – it is not going away. However, we are likely to see differences in the way that the regulation is enforced. The qualifications our contractors hold and the trade bodies in which they are registered are going to change, with the need for contractors to hold recognised qualifications in both the UK and Europe. The management of the quota system and reporting requirements is – at the time of writing – no closer to being confirmed.

Covid-19

Adding to the mix is the Covid-19 pandemic. The cooling industry has responded well to the demands of the pandemic and its role in keeping essential services running should not be forgotten. Key maintenance has continued at hospitals, supermarkets and food processing plants where refrigeration, air conditioning and ventilation has been important in helping society to cope with the pandemic.

Unfortunately, the hospitality sector and its supply chains have been hit hard by lockdowns and other restrictions. This looks set to continue over the winter period as infection rates rise again.

Refrigerants supplied by A-Gas have been critical in keeping the country running. I do not see this changing in the coming months. Another year of uncertainty is ahead of us. We are used to managing change in the cooling industry and I have no doubt that again we will rise to the challenges ahead.