12 February 2026

|

Neil Roberts, Technical Sales Director at Climalife, considers the likely direction of GB F‑Gas legislation and what it means for refrigerant selection and system specification moving forward.

In December 2022 the Department for Environment, Food and Rural Affairs (Defra) published its review of the F-Gas regulation (EU 517/2014) and the RACHP industry waited with bated breath for the expected F-Gas revision proposals.

The EU published its proposals in 2023 and adopted a new F-Gas regulation in March 2024 (EU 2024/573), but in Great Britain (Northern Ireland must still follow the EU F-Gas Legislation) the wait went on until, perhaps rather aptly, on 5th November 2025 a consultation for a new GB HFC phasedown was launched and industry were given just six weeks to assess the impact and respond to the proposal.

The consultation closed before Christmas and (at the time of writing) we are now back to waiting for Defra to announce the outcome of the consultation and the proposal for the final regulation.

What are the proposals and how are they likely to affect refrigerant choice?

The first point to emphasise is that this is not a copy-paste of the EU F-Gas regulation; Great Britain is following a different route to reduce emissions of high-GWP F-gases. The Defra proposal only concerned the HFC phasedown schedule. All other aspects, e.g. training, certification, leak checking, placing on the market prohibitions etc. are still subject to compliance with the EU 517/2014 retained legislation which is still valid in GB.

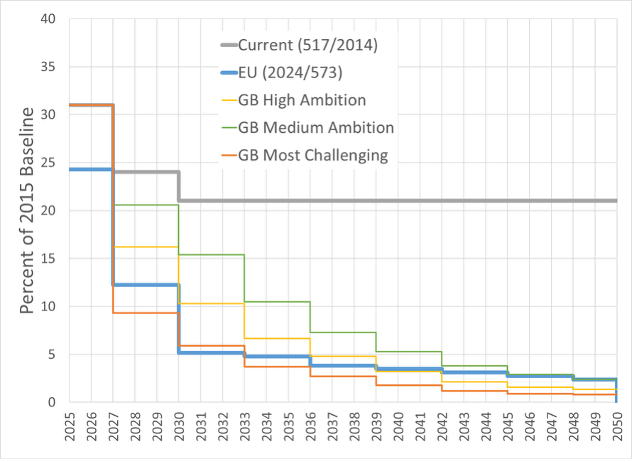

Defra published three new HFC phasedown scenarios (Figure 1) it referred to as “High Ambition”, “Medium Ambition” and “Most Challenging” of which the “High Ambition” was Defra’s preferred option with the “Most Challenging” being seen as potentially too difficult for industry to achieve.

Figure 1 - Defra HFC Phasedown High and Medium ambition scenarios

Whatever the outcome of the consultation, it is very clear that the HFC phasedown will go far beyond the 79% reduction (compared to 2015) mandated in the 2014 legislation, with all the Defra scenarios introducing increased reductions as early as next year. This should have a significant impact on refrigerant choice for new installations as the availability of refrigerants with a GWP of >1000 is likely to be affected during the lifetime of the equipment and there are very few retrofit options available that are compliant with current legislation.

What refrigerants should be used for new installations?

Let’s be very clear, specifying a refrigerant with a GWP >1000 for a new installation should only happen if there are genuinely no other practical options. Although the >1000 GWP products are available today and there are no further GWP based bans, the phasedown schedules proposed will limit availability of virgin product over the coming years, which can be offset to some degree by using reclaimed product for service requirements, but why take this route when there are good low-GWP options available for the majority of applications.

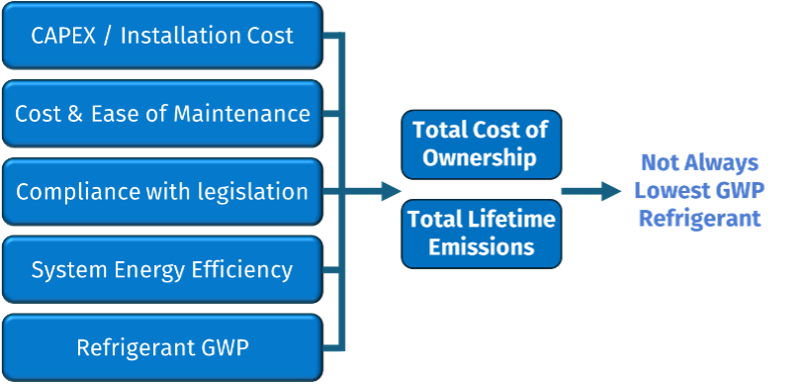

When choosing a low-GWP option there needs to be a change in the mindset used. Too many end users make the choice based on the installation cost alone, ignoring the ongoing cost of operation and the potential future availability of the refrigerant.

Key Decision Criteria

Within the EU and GB there are government programmes to encourage the use of energy efficient technologies, initially to help achieve Net Zero emissions targets but also to try to ensure the demand for electricity does not exceed the supply. Within the RACHP industry system choice should not just be made on the GWP of the refrigerant or the initial cost of installation. Over the lifetime of the system, energy efficiency is likely to have a much bigger financial impact than the installation cost, a large effect on the total emissions from the system and failure to choose a low-GWP refrigerant could have a very significant impact on the system longevity.

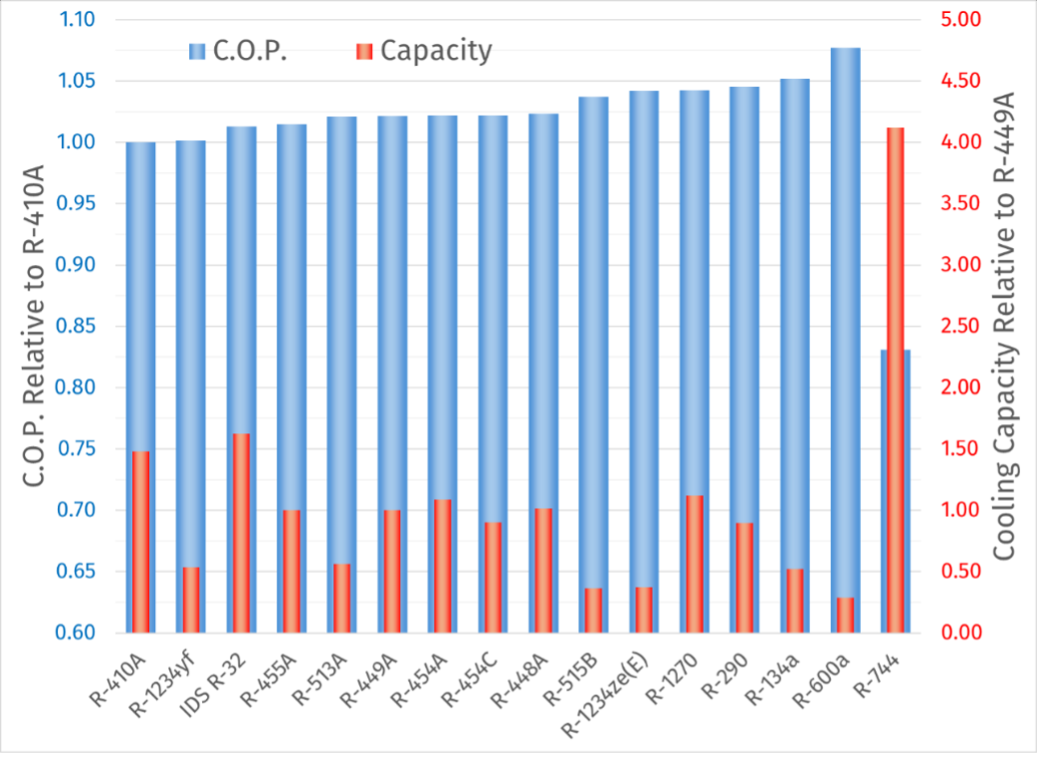

How many of us can honestly say when specifying a project that the most important factor considered is the energy efficiency? There are, of course, many different factors that define the energy efficiency of a system, but when it comes to refrigerant choice each refrigerant has a fundamental thermodynamic energy efficiency at a given set of conditions (an example is given in Figure 2).

Figure 2 - Thermodynamic performance calculations at mean evaporating temperature=-35°C, Mean condensing temperature=25°C, evaporator superheat=8K (5K R-744), compressor isentropic efficiency 65%, Liquid subcooling=2K, Suction temperature=-15°C (R-744 -22°C). R-744 system is a basic booster system.

If so many low-GWP options are available, why aren’t they used more widely?

For an industry that has been in constant flux over the last 35 years it seems strange to say there is a very conservative approach to new products and technologies. The fastest rate of change has always happened at the point where there is no longer a choice, for example CFCs and HCFCs were used right up to the point where they were banned and then the largescale switch to retrofit options took place. This time it is different, for a system that is designed for a non-flammable refrigerant there are very limited retrofit options with a GWP <1000 and virtually no retrofit options with a GWP <500.

Although the lower-GWP options do tend to have a higher installation cost than the high GWP options, the main barrier to change appears to be the lack of knowledge on use of standards and legislation that already apply to current high-GWP installations but are often overlooked. When using many low GWP options it is especially important that standards and legislation are applied correctly to ensure the safety of the technicians and the end users.

For example, compliance with the refrigerant charge restrictions and other safety requirements in EN378 applies to all refrigerants, the Pressure Equipment Safety Regulation (PE(S)R) applies to all systems above 0.5 bar pressure and the Dangerous Substances and Flammable Atmospheres Regulation (DSEAR) applies to all refrigeration systems using a refrigerant with the H280 hazard phrase (contains gas under pressure) on the Safety Data Sheet.

The use of lower-GWP refrigerants is becoming commonplace in AC with R-32 and R-1234ze widely used but in the refrigeration industry many commercial (non-retail) and light industrial systems are still being specified with high GWP refrigerants. Those trailblazing companies that have embraced the low-GWP A2L opportunity have found that after an initial learning curve, using products such as R-454A, R-454C and R-455A have become routine and relatively straightforward. With system sizes up to 440kg of A2L refrigerant in a single circuit, there are no real excuses for not using a low-GWP option today and the team at Climalife are always available for advice on product selection and compliance with standards and legislation.