31 March 2022

|

ADVERTORIAL

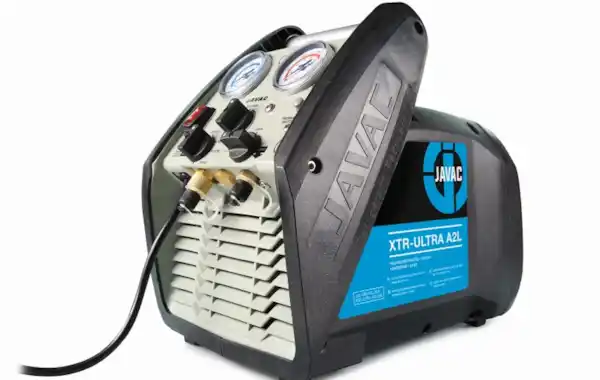

As sales of refrigeration units, air conditioning systems and heat pumps soar, engineers increasingly need products that support them on all fronts. Basically, they need to be able to work at speed, but they need to be safe and effective too. When it comes to recovering refrigerant gases and liquids, the XTR Ultra A2L from JAVAC is proving to be the engineer’s perfect business partner.

It’s fast

With a recovery rate of 120kg/hr the XTR Ultra A2L is a standout refrigerant recovery unit, but if you want to go even faster, then you can use the push-pull technique, which can achieve an incredible 420kg/hour. It’s not often used because it’s not always accessible on some plant if a liquid connection is not available. But another reason it’s not used is because it’s not widely known or practised. If you’d like to know more, read on.

It is known as push-pull because we pull the liquid refrigerant out under displacement. This works simply by connecting the liquid port of a dual valve/port recovery cylinder straight to the liquid side of the plant. We then connect the inlet (LP) of our recovery unit to the vapour port of the same recovery cylinder and recover the vapour from the top of that cylinder. This causes a pressure drop in the cylinder and a differential between the cylinder and the plant. The liquid has only one option, and that is to race into the cylinder as fast as the hose size will let it.

By connecting the discharge of the recovery unit back into the vapour side of the plant, we employ 'push'. This might sound odd but what effectively happens is the hot, high pressure discharge from the recovery unit increases the pressure over the remaining liquid in the plant and pushes it into the recovery cylinder. Initially there’s a steady rise in the cylinder weight, then accelerates as the recovery unit discharge increases the temperature and pressure in the plant. If we can swap the cylinders fast enough, that’s when 420kg/hour is achievable, not just with the XTR Ultra A2L, but with any recovery unit.

It’s safe

Safety is vital, given the flammability of some gasses. And a spark from an IEC lead could potentially have huge consequences, not an acceptable risk on any site. To combat this, the XTR Ultra A2L comes with a built-in 5-metre 240 volt glanded power lead which averts any chance of a spark occurring in the unit from the power source. To further prevent any chance of a spark, the unit also comes fitted with UL listed switches. The unit is also cool to the touch, has refrigerant connections that point down away from your eyes, thermal overloads and circuit breakers. The XTR Ultra A2L is compatible with all common refrigerant gases including R32 and all other A2L gases, R1234YF, CFCs, HFCs, HCFCs and A and B variations.

It’s convenient

Engineers have enough to carry on a repair or service visit, and our unit’s been designed with convenience in mind. The XTR Ultra A2L is compact, measuring only 320 x 220 x 260mm, has a carry handle that makes it very portable and, weighing in at only 8.4kg, it’s one of the lightest recovery units on the market.

Like all JAVAC products, this unit is built to stringent standards of performance and quality and comes with a 12-month warranty. And, since its launch last year, the XTR Ultra A2L has become the best-selling product in the company’s product range. They say good things come in small packages, and this one packs a punch too.

Tools Talk is sponsored by Aspen Pumps Group.