21 May 2025

|

ADVERTORIAL

Driven by PFAS regulations and the desire to create more sustainable, cost-effective refrigeration systems, many supermarket and light industrial operators have moved to CO₂ refrigeration as a safe, future-proof alternative to high-GWP conventional refrigerants.

While CO₂ systems perform exceptionally well in cooler climates and offer strong sustainability benefits, their efficiency can decrease in high ambient temperatures. Read this article to learn how the PX G1300 pressure exchanger can improve the performance of CO₂ systems by reducing energy costs, increasing system stability, and minimising reliance on water spray systems.

How the PX G1300 works

At its core, the PX G1300 pressure exchanger improves the efficiency of a CO₂ refrigeration system by recovering high-pressure energy from the gas cooler outlet that would otherwise be wasted. It expands the refrigerant, like a valve, but recovers the expansion energy and provides compression. This reduces the workload on the main compressor rack, lowering energy usage and increasing system capacity.

The PX G1300 also reduces the flash gas that needs to be processed by medium-temperature (MT) compressors, increasing system capacity and stability in warm weather.

Ultimately, pressure exchangers have been applied in CO₂ refrigeration systems as a compact solution that helps users reduce energy costs, minimise or eliminate water usage, and protect against heatwaves.

According to Tom De Witte, Managing Director at Delhaize in Waregem, Belgium, the energy and cost savings are significant benefits for his business: “The biggest advantage of the PX G1300 installation is that we can save on our energy bill. Since our cooling is our biggest energy consumer, this setup allows us to save up to 15% annually.”

Field results

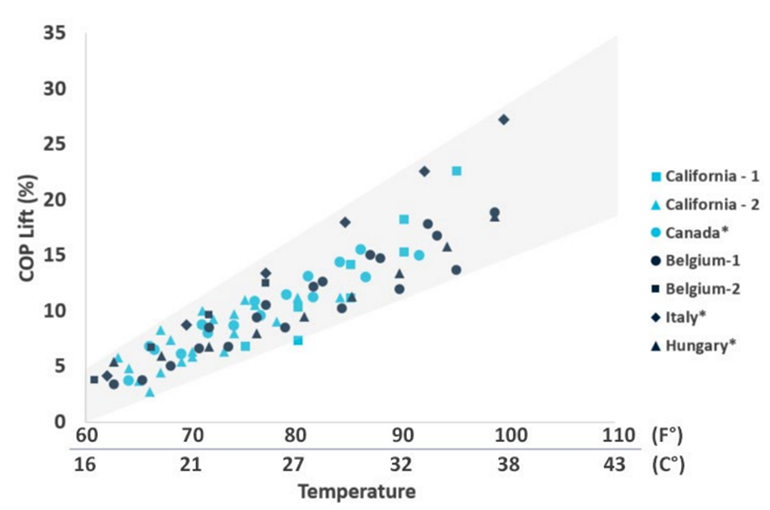

In the summer of 2024, Energy Recovery conducted a rigorous measurement and validation program across multiple global sites. The study showed that the PX G1300 delivered meaningful energy savings across a wide range of system sizes, configurations, and weather conditions.

COP lift percent across multiple sites in North America and Europe. Each point represents an average of roughly two hours of data. *Indicates analysis from OEM partners

The results of this study include:

• The PX G1300 is projected to deliver maximum annual energy savings of up to 15%.

• By reducing the flash gas processed by MT compressors, the PX G1300 can also increase system capacity by up to 15% at 35°C. This can provide up to 6°C of increased design temperature, safeguarding systems against heatwaves and high-pressure discharge failure.

• Field data demonstrated that the PX G1300 helps reduce pressure fluctuations in CO₂ refrigeration systems, enabling system optimization and tighter control settings for additional energy savings.

Additionally, new site data from a 217kW store in Northern California showed that incorporating the PX G1300 allowed the supermarket to eliminate 98% of their annual CO₂ system water use.

Learn more about the field results of Energy Recovery’s PX G1300 pressure exchanger by reading our whitepaper.

To see how the PX G1300 is helping supermarkets save water, read our case study.