02 September 2016

|

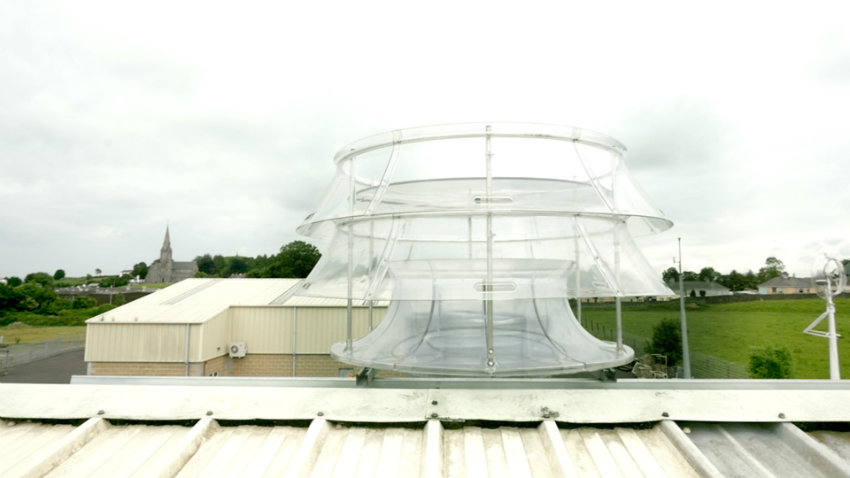

Jim Smyth, CEO at onesynergy, creator of the PAVEL air extraction unit, discusses how ground-breaking air ventilation components can combat high energy prices and consumption levels.

Energy consumption in buildings and properties continues to spiral, despite warnings of an energy shortage, and the damaging effect it is having on our environment. Between 2014 and 2015, energy consumption in the UK grew by 1.9 per cent (source - Gov.uk). Not only is the consumption of energy increasing, but so is its price.

Market experts at ICIS, an independent authority on UK electricity market pricing, have revealed that in the second quarter of 2016, the price of gas climbed 29 per cent, while wholesale electricity prices swelled 25 per cent (source - ICIS). The price of energy and its consumption is clearly a pertinent issue for the UK.

Market experts at ICIS, an independent authority on UK electricity market pricing, have revealed that in the second quarter of 2016, the price of gas climbed 29 per cent, while wholesale electricity prices swelled 25 per cent (source - ICIS). The price of energy and its consumption is clearly a pertinent issue for the UK.

New builds and existing buildings must prioritise energy efficiency

Buildings must become more energy efficient. The Concerted Action for the Energy Performance of Buildings Directive (CA EPBD) is an organisation which aims to reduce energy use in European buildings through the exchange of knowledge and best practices in energy efficiency and energy savings.

This organisation has set out its own goals for new builds to follow in Europe – that all public buildings should be Nearly Zero Energy Buildings (NZEB) by 2018, and that every new building should adopt this criteria by 2020. However, when it comes to the energy efficiency of buildings, finding ways to retrofit existing buildings is equally as important.

The UK government have stated that they are aiming for an 80 per cent reduction in emissions by 2050, and if these targets are to be met, 28 million buildings must be retrofitted (source - Carbon Action 2050). This highlights that there are considerable opportunities in both the new build and retrofit market to combat energy inefficiencies.

This organisation has set out its own goals for new builds to follow in Europe – that all public buildings should be Nearly Zero Energy Buildings (NZEB) by 2018, and that every new building should adopt this criteria by 2020. However, when it comes to the energy efficiency of buildings, finding ways to retrofit existing buildings is equally as important.

The UK government have stated that they are aiming for an 80 per cent reduction in emissions by 2050, and if these targets are to be met, 28 million buildings must be retrofitted (source - Carbon Action 2050). This highlights that there are considerable opportunities in both the new build and retrofit market to combat energy inefficiencies.

Content continues after advertisements

Shift in energy-efficient ventilation technology

Improving ventilation and heating components in buildings can greatly impact energy usage. In the farming and agricultural sector in particular, it is heavily populated with inefficient ventilation systems such as wall and ceiling inlets, monopitch buildings and mechanical fans – all of which are tricky to maintain. This lack of proper ventilation can be detrimental in live environments.

The need for energy efficient and sustainable products has been met with the introduction of innovatively designed, natural air extraction units, where air is moved by natural forces into the building through ventilation, and leaves the building through cowls or vertical ducts. These ground-breaking air extraction units overcome the inefficiencies, not only of the traditional inlet or fan ventilation options, but also standard air extraction units.

Thanks to their aerodynamic design, these pioneering air extraction units can halve the energy consumption of the extractor fan; dramatically reducing energy costs for the building. The question is, exactly how does the design of these ground-breaking units differ from the standard units?

The need for energy efficient and sustainable products has been met with the introduction of innovatively designed, natural air extraction units, where air is moved by natural forces into the building through ventilation, and leaves the building through cowls or vertical ducts. These ground-breaking air extraction units overcome the inefficiencies, not only of the traditional inlet or fan ventilation options, but also standard air extraction units.

Thanks to their aerodynamic design, these pioneering air extraction units can halve the energy consumption of the extractor fan; dramatically reducing energy costs for the building. The question is, exactly how does the design of these ground-breaking units differ from the standard units?

Modern air extraction units explained

Standard units impose additional running costs for the building’s owner due to the extractor fan having to work tirelessly to overcome the associated pressure drop. However, these newer units instead contain patented technology. This means that the unit can achieve optimum air flow efficiency via the gradual deceleration of air and its gentle diffusion into the surrounding air at low velocity.

The installation of this revolutionary air ventilation component would therefore mean that the extractor fan would not have to work as hard, saving both energy and money. Whilst this may sound like a high-tech and expensive solution, in fact, the payback for innovative products such as these are minimal. According to current electricity prices, the building owner would receive a return on their investment within two years.

These innovative products are suitable for a whole range of environments, from agriculture and farming, to commercial and residential buildings – and installation is unproblematic too. Whether it is a new-build or a retrofit project, these units are the ideal ventilation solution. In a retrofit project, it can be placed with ease directly onto existing ductwork to replace standard, more archaic-style units.

Unlike other mechanical duct systems, these newer, more efficient units also do not contain any moving parts, and therefore require minimal maintenance. These units can also be assembled at the point of fixing and do not require lifting equipment to raise and position on top of a roof.

The aesthetics of a building is also an important consideration when choosing to invest in ventilation products, especially for retail spaces, offices and residential properties. These units are ideal as they come in a wide variety of colours, and can be bespoke designed to match each individual space.

The installation of this revolutionary air ventilation component would therefore mean that the extractor fan would not have to work as hard, saving both energy and money. Whilst this may sound like a high-tech and expensive solution, in fact, the payback for innovative products such as these are minimal. According to current electricity prices, the building owner would receive a return on their investment within two years.

These innovative products are suitable for a whole range of environments, from agriculture and farming, to commercial and residential buildings – and installation is unproblematic too. Whether it is a new-build or a retrofit project, these units are the ideal ventilation solution. In a retrofit project, it can be placed with ease directly onto existing ductwork to replace standard, more archaic-style units.

Unlike other mechanical duct systems, these newer, more efficient units also do not contain any moving parts, and therefore require minimal maintenance. These units can also be assembled at the point of fixing and do not require lifting equipment to raise and position on top of a roof.

The aesthetics of a building is also an important consideration when choosing to invest in ventilation products, especially for retail spaces, offices and residential properties. These units are ideal as they come in a wide variety of colours, and can be bespoke designed to match each individual space.

Forward-thinking air extraction units are the future for the 21st century energy market

The price of energy for the UK is likely to experience some turbulence in the coming years, as its energy system attempts to recover from the closure of several power plants. However, if UK businesses and homes invest in these innovative air extraction units, then the price of energy will be less of a concern as consumption levels will automatically drop. Energy-efficient and aerodynamic air ventilation components are the future.