15 December 2021

|

Neil Roberts, senior technical sales manager at Climalife, highlights why retrofitting refrigerants is no longer a simple process to prolong the life of a non-retail refrigeration system.

Over the next few years, the F-Gas tonnes CO₂ equivalents (tCO₂e) phasedown should strongly encourage the use of low GWP refrigerant options. However, when choosing a refrigerant, it is important to note that it will be very difficult to retrofit a system designed to use a high or moderate GWP A1 refrigerant to a very low GWP A2L or A3 safety class refrigerant. This means if the refrigerant of choice for a system installed today is not low GWP and comes under pressure due to the F-Gas tCO₂e phasedown, within the next ten years, there is a real risk the equipment will have to be replaced with a system designed for a low GWP alternative. Various organisations have quoted many times that the average refrigerant GWP by 2030 will need to be around 400 and by 2036 around 300.

In new equipment, the use of any refrigerant with a GWP significantly higher than these average values should be considered at risk of not fulfilling the expected or desired lifetime of the equipment. Of course, our industry has always been used to retrofit options to prolong equipment life, but this ‘escape road’ looks like it is now closed.

Using theoretical cycle calculations and considering what current standards and regulations apply, we can explore how low GWP options compare and what is required to comply with those standards and regulations.

Single compressor or non-retail commercial, remote condensing unit systems

Under the F-Gas regulation (2014), since 2020 it has been forbidden to install new stationary refrigeration equipment (for a product temperature > -50°C) using a refrigerant with a GWP of 2500 or higher if the refrigerant charge size is 40 tonnes CO₂ equivalents (tCO₂e) or higher (e.g. 10.2kg of R404A).

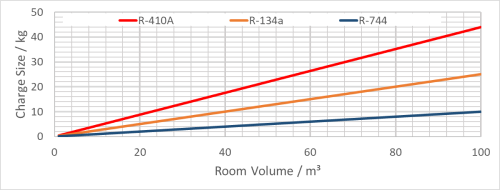

The EN 378 standard covers this application. This standard provides guidance on the maximum refrigerant charge that can be safely used and applies to all refrigerants, even non-flammable A1 refrigerants (Figure 1).

Figure 1 – Charge size restrictions under EN 378 for some non-flammable A1 refrigerants

Within EN378, refrigerants are treated differently depending on their safety classification, with refrigerant charges increasing as the risk decreases. For example, whilst the maximum refrigerant charges for A2Ls are lower than for non-flammable HFC refrigerants, they are still significantly higher than the highly flammable A3 refrigerants (Figure 2).

Figure 2 – Charge size restrictions under EN 378 for R290, R454C and R455A

As shown in figure 2, in this type of application, relatively large maximum charge sizes up to a charge size of 84kg can be used. This opens up the opportunity to consider A2L refrigerants for many applications where a remote condensing unit is used, and the compliant charge sizes for A3 refrigerants are insufficient.

There are three options with a GWP below 300 that are good candidates to replace R404A, namely R454A (238 GWP), R 454C (148 GWP) and R-455A (148 GWP). Theoretical cycle calculations for all these options compared to R404A, giving the relative capacities and coefficient of performance (COPs), are shown in figures 3 and 4.

Another low GWP option that might be considered is, of course, carbon dioxide (R744). R744 has the advantage of being safety class A1 but still has charge limitations (figure 1) and typically has low COP. Applying theoretical cycle calculations, with compressor efficiencies based on OEM data, we can consider a hypothetical application that delivers 10 kW MT and 4kW LT refrigeration at a 32°C ambient design condition, a R744 booster system is compared to two individual refrigeration systems (MT & LT) using R454C at the design condition (figure 5) and a more typical operating condition of 15°C ambient temperature (figure 6).

As can be seen, the differences in COP and therefore energy consumption are not trivial, leading to higher operating costs and higher total system emissions (which include emissions from power generation) when using R744 compared to systems operating with the low GWP A2L options. Therefore, selecting a technology with high total emissions completely undermines the whole point of using a low GWP option. This example highlights the importance of considering all the sources of emissions before selecting a low emissions technology.

Another regulatory consideration for this type of application is the Pressure Equipment Safety Regulation (PE (S)R), which is the UK legal requirement of the Pressure Equipment Directive (PED). Under PE(S)R, the low GWP A2L refrigerants (except R1234ze) fall into Fluid Group 1, which, compared to A1 refrigerants, lowers the threshold levels where more stringent safety requirements are needed.

For example, consider a system with a 3-litre liquid receiver on the high-pressure side:

If this system were operating with R404A, R448A or R449A, which are fluid group 2, it would be PE (S)R Cat I, which can be self-certified by the manufacturer without notified body involvement using industry-standard brazing qualifications.

If a similar system were designed to use an A2L refrigerant such as R454A, R454C, R455A (fluid group 1) or high-pressure R744 (fluid group 2), then this would be PED category II requiring notified body approval for brazing, system certification, quality assurance procedures for production and pressure testing with witnessing of some system pressure tests also required. These increased requirements when changing from moderate pressure A1 refrigerants to either flammable or high-pressure A1 refrigerants are the main reasons it would not be practical to retrofit existing equipment to these products in the field.

When designing systems with A2L refrigerants, it is advisable to minimise the refrigerant charge by minimising the size of liquid receivers and considering using microchannel condensers. This will minimise the risk and environmental impact, maximise the opportunities and reduce the regulatory requirements.

The time for change is now!

Whilst the availability of moderate to high GWP refrigerants is still good, it is easy to be lulled into the false sense of security that the time to change to low GWP options is somewhere in the future. However, systems that are being installed today run a very high risk of not fulfilling their expected lifetime due to the choice of an unsustainable refrigerant.

Low GWP refrigerants are readily available, and the availability of suitable equipment is rapidly increasing, meaning there is no reason why a sustainable low GWP can’t be installed today. In many cases, improved energy efficiency can be achieved using A2L refrigerants, lowering operating costs and reducing emissions for the expected lifetime of the equipment.

It is human nature to try to avoid change, but this one is inevitable, so while there is still time, why not get ahead of the legislative curve and steal a march on your competition?

Figure 3 – Capacity comparison vs R-404A at MT and LT conditions

Figure 4 – COP comparison vs R-404A at MT and LT conditions

DT for transcritical =2K, DT for subcritical =10K, evaporator superheat =5K, suction line superheat= 8K, compressor isentropic efficiencies - R-744 MT=68%, LT=48% - R-454A/R454C/R-455A MT=68%, LT= 67%, R-454A/R454C/R-455A liquid subcooling = 2K.

Figure 5 – COP vs R-744 at 32°C ambient design condition

Figure 6 – C.O.P. vs R-744 at 15°C ambient condition