22 March 2023

|

Temperature control specialist ICS Cool Energy has collaborated with a leading international brewery to enable temporary storage capabilities at its UK manufacturing plant.

Preventing spoilage, preservation of flavour and aroma, quality and consistency control were the main necessities for the brewery when it was looking for a partner to trial temperature controlled storage for its reactor vessels. The brewery required a reliable containerised solution, that would enable it to keep its fermentation vessels at a specific temperature, in the middle of the plant.

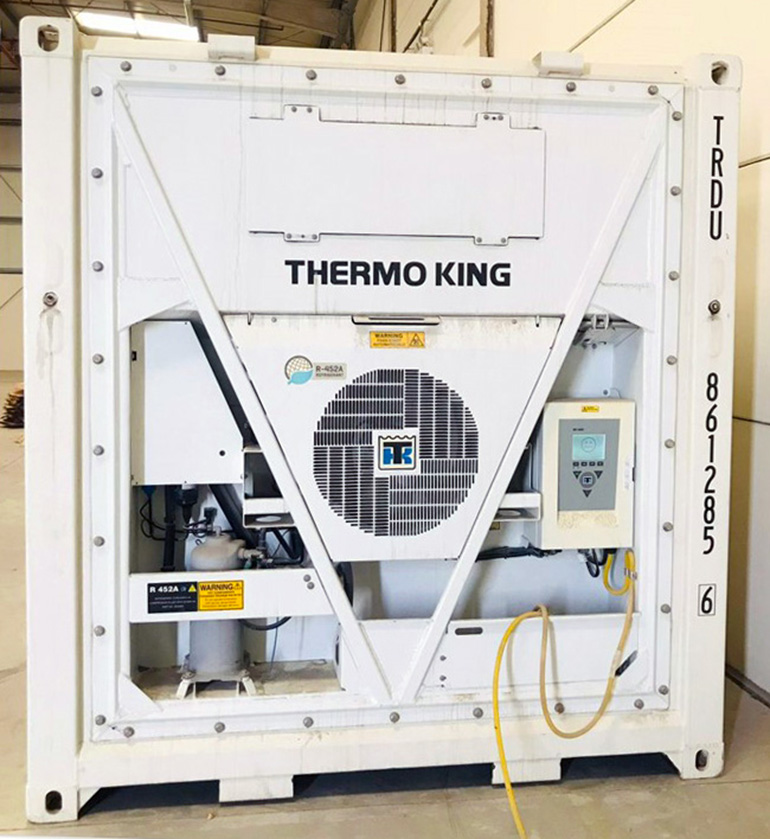

Additionally, the storage needed to be easily accessible for a forklift or a motorised pallet truck to enter. ICS Cool Energy provided two customised, high-cube 40-feet refrigerated container units with heavy-duty ramp.

“Consistency is key in the brewing process and keeping ingredients at a steady temperature is essential for maintaining quality control. If the temperature fluctuates, it can impact the brewing process, resulting in inconsistent batches and ultimately affecting the taste and quality of the beer,” said Andy Delday Roberts, UK sales manager-hire at ICS Cool Energy.

“Certain ingredients and reactor vessels can be highly sensitive to temperature fluctuations and need to be stored for a prolonged period of time. If exposed to temperatures that are too high or too low, they can become damaged and lead to spoiled beer. By storing ingredients in our cold storage containers, at a consistent temperature, the brewery can effectively prevent spoilage and maintain the quality of their brewing process and end products.”

The ICS Cool Energy cold store solutions are said to deliver high cooling capacity in combination with precise temperature control from +30⁰C to -40°C, even in the most severe applications with high ambient temperatures, frequent door openings, long running hours etc. The containers feature refrigeration units originally designed for seagoing reefer applications and can be plugged in the 360-500 Volt 50 or 60 Hz power supply to ensure steady cold or frozen temperatures in the container.

By using containerised units, the brewery avoided the investment required to turn a large part of the plant into a cold room. This also contributed to significantly lower energy consumption and more flexibility for the storage of the vessels. Following the initial 12-months hire contract and successful tests, the brewery decided to extend the hire of the cold store solutions to a 5-year period.