18 December 2019

|

Over the past 30 years, from small beginnings BITZER has grown to become one of the largest independently-owned compressor manufacturers in the world. We look back on the company’s journey from fledgling to global leader.

When Martin Bitzer founded a small refrigeration engineering company called Apparatebau für Kältetechnik (later to become BITZER) in 1934, few could have predicted the company’s remarkable growth and development over the decades that followed.

When Martin Bitzer founded a small refrigeration engineering company called Apparatebau für Kältetechnik (later to become BITZER) in 1934, few could have predicted the company’s remarkable growth and development over the decades that followed.

|

|

In the early days, the company manufactured simple mechanical expansion valves. This humble yet reliable system component was followed by a sequence of rapid developments, and it wasn’t long before the first BITZER open-drive compressor, known as the Type 1, rolled off the production line, closely followed by the first shell and tube condensers and liquid receivers.

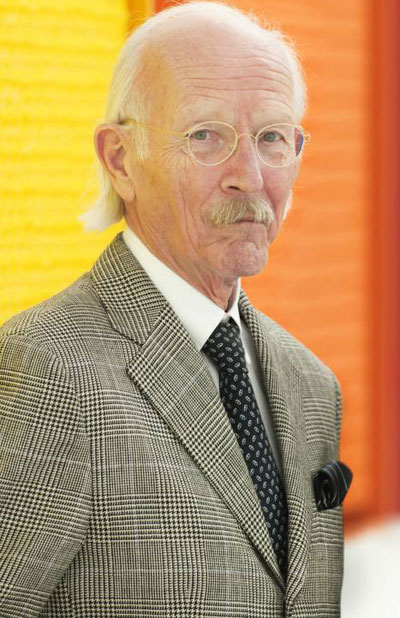

BITZER was now in business, making some of the key system components required for the roll-out of the modern cold chain infrastructure needed by the burgeoning food industry. In the decade following came the first BITZER hermetic and semi-hermetic compressors, ushering in a new era of improved energy efficiency and refrigerant containment. It was huge leap forward from the notoriously leaky and inefficient open-drive compressors of the past. As a result of such pioneering innovations, by 1959 Martin Bitzer had expanded the company to 206 employees and was exporting its highly regarded products to 56 countries. Ownership of the company passed at the beginning of the Sixties to Ulrich Schaufler, a graduate engineer with a passionate interest in refrigeration technology. It was an important development, and Ulrich Schaufler sharpened the company’s focus on high quality production, and redoubled the emphasis on advancements in engineering and design, resulting in rapid progress in compressor technology.  Peter Schaufler

When Ulrich Schaufler’s son Peter inherited the business in 1979, BITZER had annual sales of DM30 million. The handover to the creative and entrepreneurial Peter Schaufler marked the beginning of a period of rapid commercial and technical transformation. Under Peter Schaufler’s stewardship, in the years that followed sales increased to E740 million and the company founded over 40 subsidiaries on five continents. It also established factories in Portugal, China, Australia, South Africa, Brazil, Indonesia and the United States. During this period a number of important engineering developments were introduced to the world. The first model of BITZER’s renowned twin-rotor screw compressor was launched in the early Eighties. Refined and perfected in subsequent iterations, this highly reliable, high efficiency compressor rapidly became a trusted workhorse that remains part of the company’s core offering today. BITZER’s first lightweight aluminium compressor was introduced in the early Nineties, as part of a focus on providing solutions for transport cooling applications. Then, as the phase-out of high GWP refrigerants began to accelerate, BITZER developed the first mass-production compressor designed for use with subcritical carbon dioxide.  The BITZER production line as it was in 1980

The technology was crowned a decade later with the introduction of the company’s first compressor designed for use in high pressure transcritical carbon dioxide systems. This has since become established as the highly dependable, go-to low-GWP solution, used by retailers and the food industry the world over. Development of BITZER’s scroll compressor range in the early Noughties completed the company’s mastery of the three principle compression technologies, taking their place alongside its established ranges of reciprocating and screw compressors. Today, BITZER operates from 65 locations worldwide, and its high quality refrigeration compressors and system components are in use in virtually every country of the world, in applications spanning commercial and industrial refrigeration, marine and transport cooling, and air conditioning for buildings. With the recent launch of Green Point as the company’s specialist repair and remanufacturing arm, BITZER has effectively completed the production and use cycle, adding service and logistics to its core manufacturing activities. In addition to organic growth, BITZER has made a number of strategic acquisitions in recent years that have further extended its reach and capabilities into important contiguous areas. It acquired Denmark-based controls specialist Lodam in 2007, recently changing its name and incorporating it into the group as BITZER Electronics, to focus on developments in the rapidly developing area of controls and digital systems. Other recent acquisitions include VaCom Technologies and ElectraTherm in the USA, and Alfa-Laval’s shell and tube heat exchanger division in Italy, in the process absorbing a well-known competitor and expanding its own range significantly. In addition to his technical expertise and flair for business, Peter Schaufler was widely known as a collector and supporter of contemporary art. The Schaufler Foundation, created by Peter Schaufler before his death in 2015, continues his life’s work in combining entrepreneurship with science, research and art, under the chairwomanship of Peter’s widow Christiane. Kevin Glass, managing director of BITZER UK, says: “BITZER’s remarkable success as a company is due in large part to a combination of two powerful aspects of human ingenuity: the excellence and reliability of its engineering, coupled with a spirit of creativity and entrepreneurship on the part of those who have led the company through the years. “This has resulted in superbly designed and built products that are trusted the world over, backed by a first-rate logistics organisation. From the beginning, the company understood the critical nature of refrigeration and air conditioning in all its manifest applications, and built the products and organisation needed to support it.” What does the future hold for BITZER? “In the era of climate change and environmental protection, the strengths that contributed to the company’s success in the past will be even more important in the future. The world needs reliable, efficient cooling that can be operated with minimal impact on the environment. This is at the heart of everything we do.”  Kevin Glass F.Inst.R Managing Director, BITZER UK Limited Direct +44 (0)1908 622100 [email protected] www.bitzer.de |

Content continues after advertisements