29 July 2014

|

John Barker

John Barker High humidity in cold rooms can result in reduced energy efficiency and disruption to processes. John Barker of Humidity Solutions discusses desiccant dehumidification and the potential for heat recovery.

Anyone involved in operating a cold store will be familiar with the problems that can result from iced up evaporator coils as a result of excessive humidity in the air. Not only does this impair efficient performance, it also potentially leads to downtime for defrosting.

Dehumidification has been the accepted solution for many years, with desiccant dehumidifiers being the technology of choice in most applications. Desiccant dehumidifiers can reduce moisture levels at temperatures as low as -70°C, removing moist air from the cold room and re-introducing dried air.

Anyone involved in operating a cold store will be familiar with the problems that can result from iced up evaporator coils as a result of excessive humidity in the air. Not only does this impair efficient performance, it also potentially leads to downtime for defrosting.

Dehumidification has been the accepted solution for many years, with desiccant dehumidifiers being the technology of choice in most applications. Desiccant dehumidifiers can reduce moisture levels at temperatures as low as -70°C, removing moist air from the cold room and re-introducing dried air.

However, the operation of a desiccant dehumidifier results in the dried air that re-enters the cold room being at a slightly higher temperature than the air in the cold store. This is because as the water vapour in the air is adsorbed onto the desiccant, some heat energy transfers to the air.

Clearly this is a concern for some cold store operators as there is an inevitable – albeit small – increase in energy consumption to cool the air again.

Clearly this is a concern for some cold store operators as there is an inevitable – albeit small – increase in energy consumption to cool the air again.

Recovering heat (cold) | One solution to this problem is to use heat recovery – though in this case perhaps it should be called ‘cold’ recovery as it works in reverse to the heat recovery process used to conserve heat in buildings. This works by passing the dried air through a plate heat exchanger where the sensible heat that was gained in the desiccant rotor is given up before the air returns to the cold room. The key thing here is that there is no change in enthalpy (isenthalpic) so the dried air returns to the cold room at the same temperature as it left so there is no increase in refrigeration requirement. The key point here when selecting the best option for a particular cold store is to get the right balance of capital investment against reducing operating costs. A desiccant dehumidifier without the heat exchanger will still deliver significant energy savings by preventing the icing of the coils, more than compensating for the slight increase in temperature of the air returning to the cold room. Introduction of heat recovery will certainly increase these energy savings, but additional capital investment in a plate heat exchanger will be required – so the critical question is what sort of payback will that extra investment deliver? The answer to that is that it will depend on the individual application, there is no hard and fast rule that will cover all eventualities. So it is advisable to seek specialist advice to ensure getting the best solution that delivers the required performance with a sensible return on investment. |

How desiccant dehumidification works

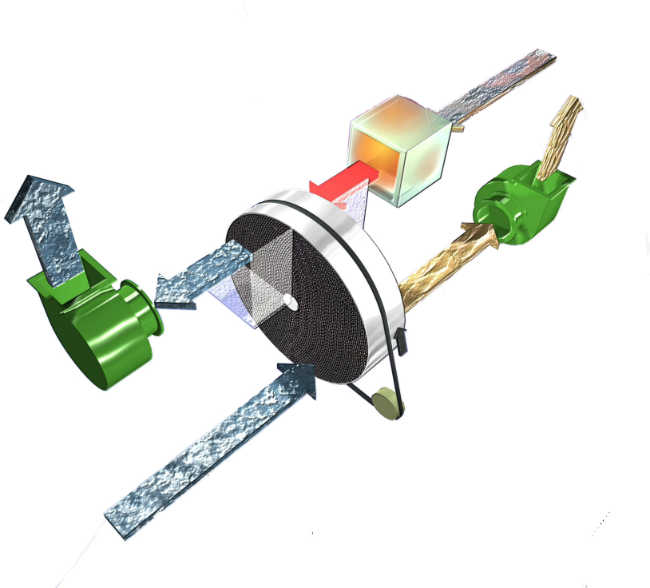

Rotary desiccant dehumidifiers work by using a desiccant substance such as silica gel to adsorb moisture from the air.

Air is drawn from the cold room through a filter and passes through a desiccant rotor (a rotating wheel containing desiccant) where it gives up most of its water vapour, so that as the air passes out of the other side of the rotor it is drier than when it entered the rotor. The moistened section of the rotating desiccant wheel then passes through another air stream that dries (reactivates) the silica gel and this moistened air is exhausted to the atmosphere.

For cold rooms, experience shows that the choice of desiccant is important, as it mustn’t deteriorate under low humidity conditions. Synthesised silica gel has shown itself to be chemically and thermally stable with low maintenance requirements as it can be washed with water.

www.humiditysolutions.co.uk

Air is drawn from the cold room through a filter and passes through a desiccant rotor (a rotating wheel containing desiccant) where it gives up most of its water vapour, so that as the air passes out of the other side of the rotor it is drier than when it entered the rotor. The moistened section of the rotating desiccant wheel then passes through another air stream that dries (reactivates) the silica gel and this moistened air is exhausted to the atmosphere.

For cold rooms, experience shows that the choice of desiccant is important, as it mustn’t deteriorate under low humidity conditions. Synthesised silica gel has shown itself to be chemically and thermally stable with low maintenance requirements as it can be washed with water.

www.humiditysolutions.co.uk

Content continues after advertisements