11 August 2017

|

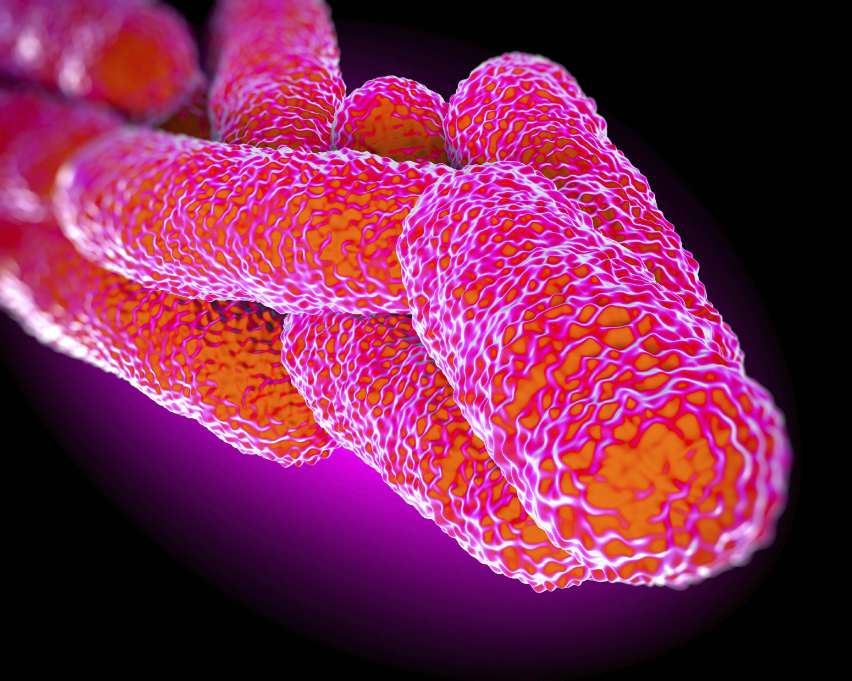

| Cooling towers are often responsible for the most widespread and high-profile cases of Legionnaire’s disease, thanks to the water conditions within these systems and their distribution of fine vapour droplets; a dangerous mix. While chemical dosing is essential in keeping cooling towers clean, inefficient use can cause other issues such as corrosion. Steven Booth, Associate Director for Guardian Water Treatment, explains how best practice maintenance and construction can improve hygiene, therefore reducing the need for excessive dosing. |

Excessive use of chemicals can result in corrosion

Excessive use of chemicals can result in corrosion We are all aware of the damage a Legionnaire’s disease outbreak can cause to human health and a business’s reputation. HVAC systems that include too much bacteria are also prone to inefficiency, with essential components clogged and therefore more power required to run the system.

Ensuring water is clean in cooling towers begins with how a tower has been constructed and the water treatment methods chosen at its inception. Some non-chemical methods, for example, seem to struggle with the demands of controlling the conditions in cooling tower water, particularly as systems age. In Guardian’s view, dosing will always be needed to ensure hygiene - even the most advanced non-chemical technologies need to be installed with a chemical back up. The amount of chemicals used can be greatly reduced, however, if proper maintenance regimes are adhered to. Cutting the overuse of chemical is important to minimise costs and corrosion – excessive bromine, for example, can degrade pipework.

Cooling tower design and layout

If a cooling tower system is designed correctly, efficient dosing and control can be maintained. Dead legs in pipework and any areas where water is allowed to collect and stagnate will increase the risk of legionella and mean that dosing may be inefficient. Poor design and badly balanced systems can also lead to water wastage and therefore unnecessary increased chemical usage.

Understand your cooling tower

Every cooling tower is different and the only way to truly apply the most appropriate water treatment programme is through continuous monitoring. Where issues are flagged up as soon as they occur, they can be dealt with swiftly, preventing major disaster at a later date. The root cause of a problem can also be identified and rectified, rather than just throwing in more chemicals which will only serve to temporarily mask the issue. This information will also steer maintenance practices, which should be based on actual usage, rather than a ‘one-size-fits-all’ approach.

Cooling tower problems

There are various types of cooling tower and evaporative condensers. In all evaporative cooling systems it is the evaporation of a small amount of water that takes waste heat away from the system – it is a very efficient method of cooling.

Cooling towers are however in essence, massive air scrubbers, and, as such the most problematic issues will arise from external contaminants entering the water supply, such as pollen or silt. These contaminants foul surfaces, contributing to conditions in which bacteria can thrive. Apart from silt, scaling, which occurs due to calcium carbonate, can build up also causing system fouling and poor water hygiene.

Bespoke approach

With cooling tower construction and usage varying from site to site, maintenance teams should be trained in a way that is bespoke to their building – a generic understanding of ACoPL8 may not be enough. How this legislation is applied to a particular situation is essential, with classroom learning only falling short of real, practical experience. Understanding the nuances of a particular cooling tower will improve maintenance regimes and allow for the correct dosage of inhibitors and biocides.

Human safety should of course be the primary concern, with building managers and installation engineers initially focused on keeping occupants safe by preventing Legionella and other waterborne pathogens. A safe approach can also be an efficient one, however, and by taking a bottom-up view, from construction through to whole-life maintenance, chemical overuse will be reduced and HVAC systems will work more efficiently, saving money in terms of repairs and wasted energy.

Ensuring water is clean in cooling towers begins with how a tower has been constructed and the water treatment methods chosen at its inception. Some non-chemical methods, for example, seem to struggle with the demands of controlling the conditions in cooling tower water, particularly as systems age. In Guardian’s view, dosing will always be needed to ensure hygiene - even the most advanced non-chemical technologies need to be installed with a chemical back up. The amount of chemicals used can be greatly reduced, however, if proper maintenance regimes are adhered to. Cutting the overuse of chemical is important to minimise costs and corrosion – excessive bromine, for example, can degrade pipework.

Cooling tower design and layout

If a cooling tower system is designed correctly, efficient dosing and control can be maintained. Dead legs in pipework and any areas where water is allowed to collect and stagnate will increase the risk of legionella and mean that dosing may be inefficient. Poor design and badly balanced systems can also lead to water wastage and therefore unnecessary increased chemical usage.

Understand your cooling tower

Every cooling tower is different and the only way to truly apply the most appropriate water treatment programme is through continuous monitoring. Where issues are flagged up as soon as they occur, they can be dealt with swiftly, preventing major disaster at a later date. The root cause of a problem can also be identified and rectified, rather than just throwing in more chemicals which will only serve to temporarily mask the issue. This information will also steer maintenance practices, which should be based on actual usage, rather than a ‘one-size-fits-all’ approach.

Cooling tower problems

There are various types of cooling tower and evaporative condensers. In all evaporative cooling systems it is the evaporation of a small amount of water that takes waste heat away from the system – it is a very efficient method of cooling.

Cooling towers are however in essence, massive air scrubbers, and, as such the most problematic issues will arise from external contaminants entering the water supply, such as pollen or silt. These contaminants foul surfaces, contributing to conditions in which bacteria can thrive. Apart from silt, scaling, which occurs due to calcium carbonate, can build up also causing system fouling and poor water hygiene.

Bespoke approach

With cooling tower construction and usage varying from site to site, maintenance teams should be trained in a way that is bespoke to their building – a generic understanding of ACoPL8 may not be enough. How this legislation is applied to a particular situation is essential, with classroom learning only falling short of real, practical experience. Understanding the nuances of a particular cooling tower will improve maintenance regimes and allow for the correct dosage of inhibitors and biocides.

Human safety should of course be the primary concern, with building managers and installation engineers initially focused on keeping occupants safe by preventing Legionella and other waterborne pathogens. A safe approach can also be an efficient one, however, and by taking a bottom-up view, from construction through to whole-life maintenance, chemical overuse will be reduced and HVAC systems will work more efficiently, saving money in terms of repairs and wasted energy.

- Guardian Water Treatment provides cooling tower construction and ongoing water treatment and has recently introduced a new bespoke training programme for cooling tower operatives to teach the requirements of ACoP L8. Training takes place on-site, covering cooling tower operation, weekly testing, as well as site-specific requirements. For more information, visit www.gwtltd.com

Content continues after advertisements